Pluri Tubular Bags

Pluri Tubular Bags manufacturers in India

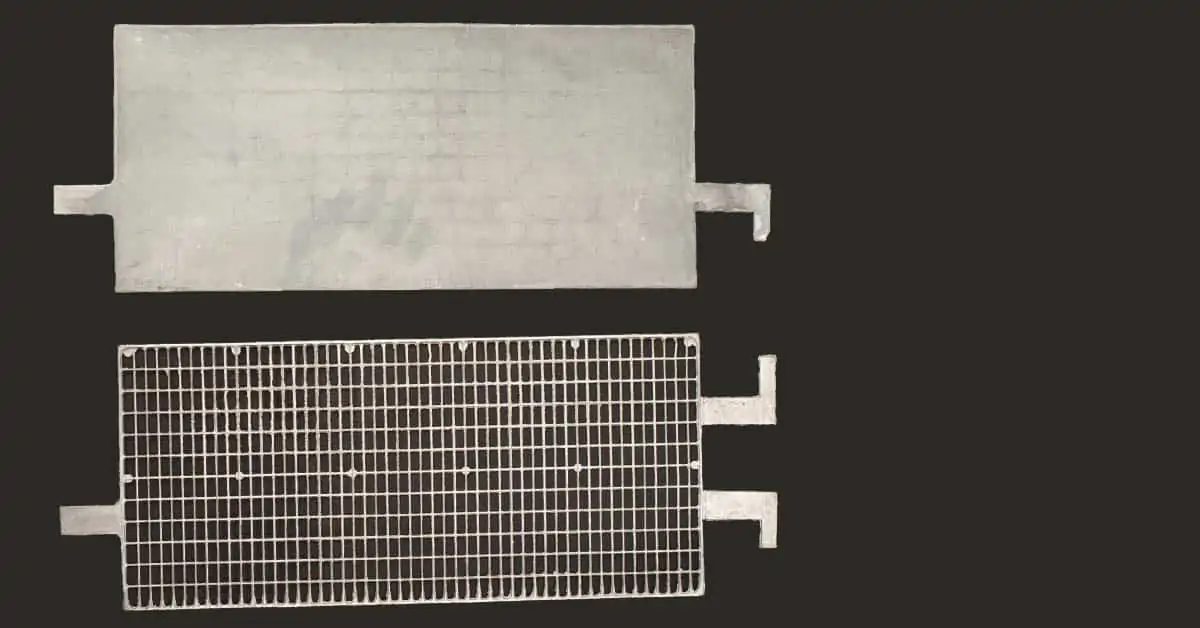

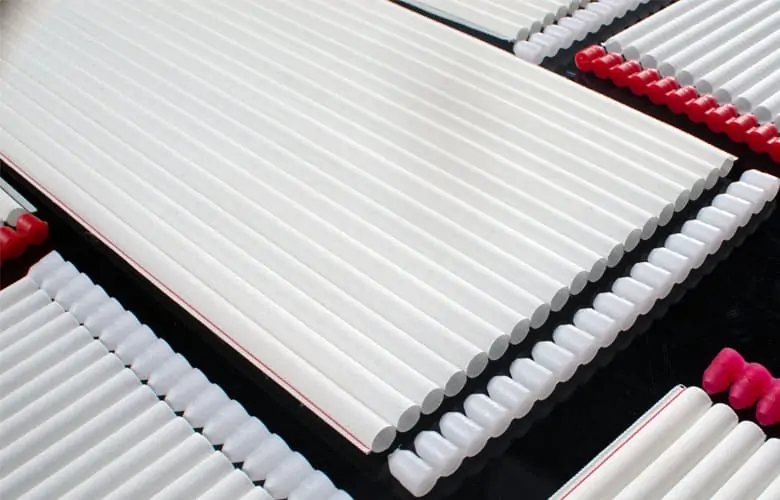

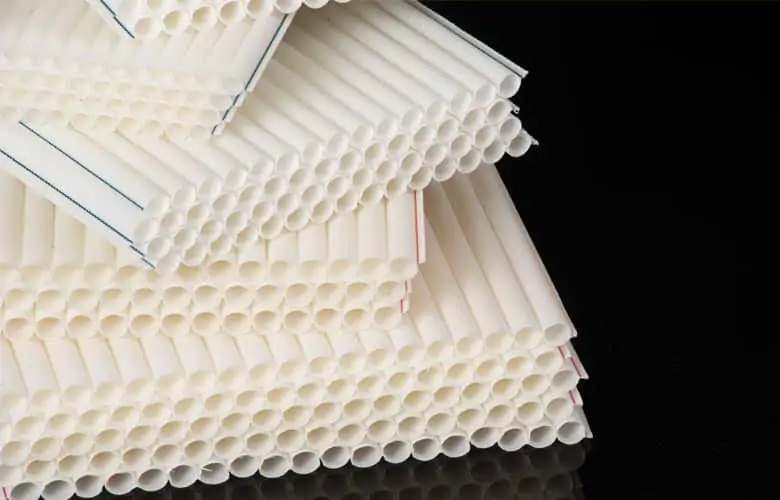

PT bags pluri tubular are manufactured from white woven polyester multi tubular fabric. Popularly known as PT Bags, tubular bags pluri bag, they are used as oxide holders for manufacturing a component of the utmost importance inside a lead acid battery – the tubular positive plate.

Trusted by the best battery

manufacturers!

Why Microtex is considered the best

PT Bag Manufacturers in India

Established in 1969,

Microtex PT Bags are known for its legendary quality

Microtex PT Bags are known the world over for their dependable & reliable performance in the battery. PT Bags manufactured by Microtex are made from selected high-tenacity polyester yarns from the best of polyester yarn manufacturers. This ensures the tubular bags do not react to the harsh acidic environment inside the lead acid battery

What are Tubular Bags?

Microtex PT Bags (Tubular bags or multi-tube Gauntlets) used in the production of tubular battery plates are an innovative and welcome import substitute for industrial lead-acid battery manufacturers in India – pioneered by the manufacturers of the legendary Microtex battery and separators, 50 years ago. A result of the persistent and completely indigenous research and inventive enterprise of our founder Mr A Govindan, who held a Patent for the Tubular Bags issued in 1975 by the Trademarks & Patent Registrar, India.

- Engineered woven Tubular Bags are made from technical textiles & are used as oxide holders for the production of tubular positive plates in lead acid batteries.

- Microtex Tubular Bags are stringently tested in house for chemical and electrical properties, meeting and exceeding the norms. High-performance batteries made from our PT Bags have met the severe endurance test as per IS 1651 in Stationary cells and Life-cycle tests as per Indian Railway specifications for high cranking currents in Diesel Locomotive Starter Batteries.

- Microtex Tubular Bags are –

used in all tubular batteries like – - UPS, Inverter batteries traction battery manufacturers in India

- in high-end industrial applications like Railway Locomotive Battery, Train Lighting batteries and Signaling battery,

- in high-performance stationary cells – OPzS and OPzV with a designed life of 20 years – requiring a zero defect, zero failure of tubular bags,

- used by tubular battery manufacturers and for Tubular Gel battery applications both deep-cycle batteries demanding a robust construction of the Tubular Bag

- Regularly exported for naval applications in the manufacture of Submarine Batteries by world-class battery manufacturers

Pluri tubular bags for lead acid battery

MICROTEX PT Bags

Our chemical labs are equipped with state-of-the-art high-quality equipment to test our Pluri Tubular for all chemical, mechanical & electrical properties to ensure your batteries are made with the best Tubular Bags quality.

MICROTEX Tubular Bags combining the outstanding characteristics of low electric resistance, chemical cleanliness, higher porosity, smaller pore size, superior acid resistance and oxidation resistance, make it the best option for heavy duty tubular battery applications like, traction batteries, submarine batteries, stationary batteries, inverter batteries, train lighting, Locomotive starting applications and all other lead acid batteries.

- MICROTEX PT Bags for the tubular battery is regularly tested in our chemical laboratories for

- dimension stability

- oxidation resistance

- electrical resistance

- tensile strength

and are found to surpass our specifications

Properties of high-performance Microtex PT Bags for batteries

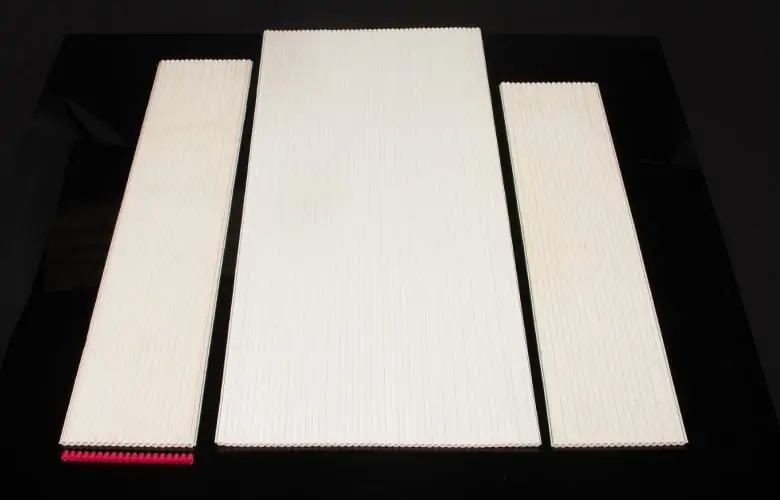

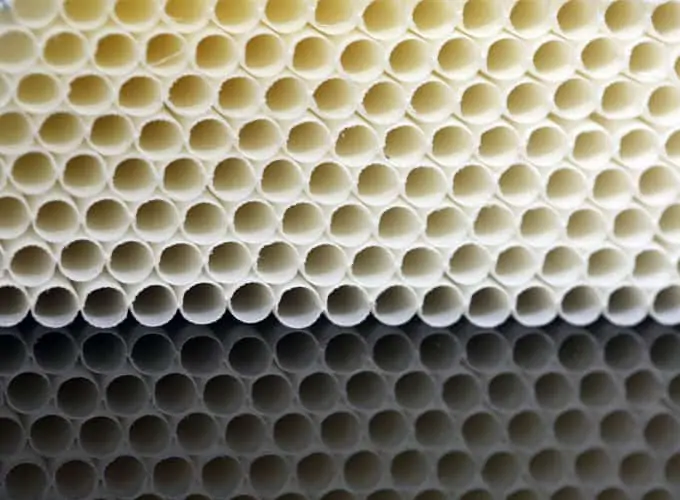

- Microtex Battery gauntlets have uniform tube diameter without any inconsistencies

- High tensile gauntlet strength; does not rupture in battery service life. Unlike non woven.

- Very low electrical resistance; unhindered battery discharge performance

- Enhanced elasticity; Resilience in compression of active materials

- No impurities present; Chemically clean & pure

- Very low weight loss; does not disintegrate inside the battery

- Excellent oxidation resistance; very long life

- Dimensionally stable; does not get affected in sulphuric acid inside the battery

- Very small pore size; Ensures retention of active mass & eliminates shedding

- Mechanically very strong; no failures due to bursting of tubes

Engineered profile; ease of use in shop floor

What sets our Tubular Bags apart from the rest?

- Chemically clean & Pure – our tubular gauntlets are free from chlorine or organic matters

- Operational Life: > 20 years

- Higher number of openings & extremely porous

- Very low electrical resistance

- Highly resilient tubular bags with high tenacity

- Excellent Burst Resistance – Our PT Bags will not burst during the service life of the battery

- Tested in diesel locomotive batteries where cranking currents exceed 2300 amp hours

- Extremely good acid resistance & resistant to electrochemical oxidation

- Made from defect free fabrics – No Pinholes or defects

- Highly elastic tubular bags for the extreme expansion contraction reactions of the active materials. will not rupture

- Pluri tubular bag HSN Code 85079010

- Delivery: fastest 3 days assured on-time delivery, every time; Guaranteed

Made in India

- High-performance Tubular Battery Gauntlets – will not puncture in service

- Reinforced double layer at selvedges ensure no active materials will come in contact with negative active materials

- Very strong & easy for dry powder filling, paste slurry or automatic wet filling machines

- Excellent battery backup

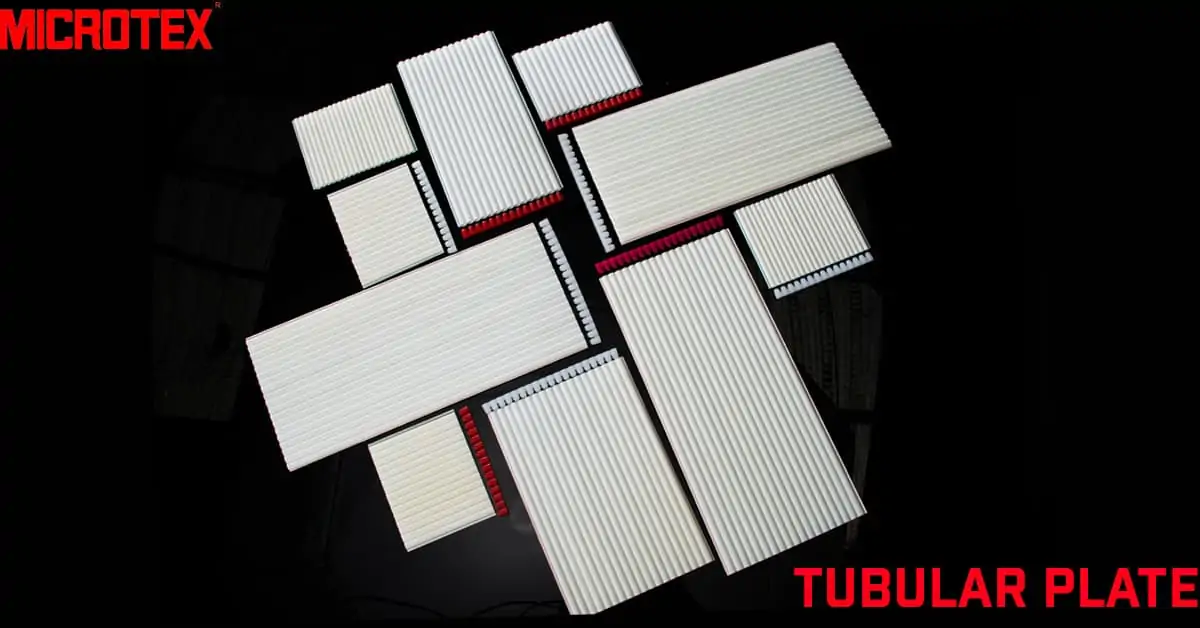

- Available in various diameters of 4mm 5mm 6mm 6.24mm 7.3mm 8mm 8.4mm & 10mm

- Impregnated with synthetic monomer resins that can withstand extreme conditions of deep cycling charge discharge cycles.

- Where the battery requirement needs deep cycling performance use only woven tubular gauntlets. Non-wovens can be used for lighter applications where the need for extreme battery performance with higher cycles is lesser.

- Does not tear or rip away at the edges inside the battery

- Price: A realistic, and competitive PT Bags price

Send us an inquiry, for Tubular Bags, now.

Microtex offers heavy duty Tubular Bags and are available in fast moving standard dimensions as below:

| 115 x 8 x 15 Tubes | 210 x 8 x 15 Tubes | 210 x 6.24 x 20 Tubes | 150 x 7.24 x 17 Tubes |

| 150 x 8 x 15 Tubes | 260 x 8 x 15 Tubes | 180 x 6.24 x 22 Tubes | 230 x 7.24 x 19 Tubes |

| 170 x 8 x 15 Tubes | 270 x 8 x 15 Tubes | 175 x 6.24 x 23 Tubes | 200 x 7.24 x 19 Tubes |

| 190 x 8 x 15 Tubes | 235 x 6 x 20 Tubes | 225 x 8.4 x 18 Tubes | 255 x 7.24 x 19 Tubes |

- Production capacity: > 1 million pieces per month

Microtex Tubular Bags are usually available ex stock. Special custom sizes are usually delivered in 3-5 days. Tubular bags dealers will find our speed of delivery very helpful.

- Tubular bags are packed in 50’s for easy insertion into the battery. They are wrapped in water proof PE bags to keep any moisture away. Placed inside sturdy master cartons. Usually dispatched in full lorry loads/small trucks , secured well & is packed suitably for safe transport.

- Microtex ensures packing for safe delivery

- All Tubular Bags come with our standard 1 year warranty

Technical Data

MATERIAL REQUIREMENTS

ITEM | TYPICAL VALUE | |

Material Type | 100% High tenacity Multi strand Polyester | |

Color | White | |

Structure | Crosswise to the tube | Polyester multifilament yarn, high tenacity |

Lengthwise | Polyester High tenacity Multi strand | |

Wall thickness | 0.35 mm | |

Weight per square meter | 700 g/m2 | |

Tube Pitch | As required (min. value = nominal diameter +1.0 mm) | |

Number of tubes | 15,19,22,46 or as required | |

Texture | Woven Cloth | |

Lateral Finish | T or C | |

| PT BAGS DIMENSIONS | TOLERANCES | ||||

| MATERIAL CODE | INNER DIAMETER | HEIGHT | ITEM | TYPICAL VALUE | |

| A GAUNTLET | 8.0 mm | 100.0 mm to 1200 mm | Inner diameter | -0 / +0.15 mm | |

| B GAUNTLET | 8.4 mm | 100.0 mm to 1200 mm | Height | ± 2.0 mm | |

| C GAUNTLET | 6.24 mm | 100.0 mm to 1200 mm | Width | ± 1.0%, with an upper limit of ± 2.5 mm | |

| D GAUNTLET | 7.24 mm | 100.0 mm to 1200 mm | Tube pitch | ± 1.0% | |

MICROTEX Tubular Bags surpass industry standards

and have been tested and certified by various battery manufacturers.

Our chemical labs are equipped with state-of-the-art high-quality equipment to test our battery gauntlets for all chemical, mechanical & electrical properties to ensure your batteries are made with the best quality Tubular Bags. Tubular bags bursting strength tester to ensure consistent quality.

| PHYSICAL AND CHEMICAL PROPERTIES | TYPICAL VALUE OBTAINED |

| Tube Bursting pressure | > 50 bars for one Minute |

| Electrical resistance | < 0.35 ohm-cm2 |

| Typical Value (average) | 0.25 to 0.35 ohm-cm2 |

| Impurities (after 2 hours reflux in H2S04 ) | |

| Chlorine | < 50 ppm |

| Metals | < 13 ppm |

| Weight loss after 7 days @ 70 ºC, In H2S04 (d=1.3) + K2Cr2O7(30g/l) | |

| a) At 25°C for 24 Hours: – Weight loss less than 0.5%. | |

| c) At 25°C for 240 Hours: -Weight loss less than 2.0%. | |

| d) At 70°C for 24 Hours: – Weight loss less than 1.0%. | |

| e) At70°C for 240 Hours: – Weight loss less than 5.0%. | |

| Increase of outside Dia of the tube at 8 Bars internal pressure | < 2% |

| Battery Life Test –Number of Charge-Discharge cycles | > 1500 Cycles |

Please click to view certificate

- Microtex Tubular Bags are supplied suitably packed for safe distant transport within India or in sea worthy pallets for exports

Please provide us with the following information to ensure that you receive the right product for years of great performance:

What is the required PT Bags dimensions in

- Length in MM

- Overall Width in MM

- Tube Diameter in MM

- No of Tubes

- And Quantity

Please click the link below to view:

Industry-leading European Battery Experts work with us

The best experts from the European battery, industry assist in the design of Microtex Tubular Bags & Processes to European Standards – Making us the preferred Tubular Bag Suppliers to India & the world.

Microtex have been manufacturing & exporting PVC Battery Separators from 1969!

Microtex timeline

May, 1969

Established as mfrs of PVC Battery Separators & PT Bags

Mr A Govindan our Founder & first generation entrepreneur, establishes Microtex pioneering the manufacture of battery separators & Tubular Bags which were import substitutes at the time. He obtained a patent for the Tubular Bags in 1975

Feb, 1977

Started exporting Traction Batteries to USSR

Not many companies in the world have the rich experience of manufacturing & exporting traction batteries from 1977. Microtex have supplied over 4500 traction batteries a year during the period

March, 1985

Approved for supply of 2V batteries for Telecom

Started supplies of 2V flooded LMLA batteries to the state owned P&T

April, 1994

Approved for supply to Indian Railways

Batteries for rolling stock applications & stationary batteries for signaling applications.

July, 2003

launched INtelliBATT 12v TT inverter batteries

Highly successful Microtex 12V flooded batteries for the huge inverter battery markets

Feb, 2005

Started manufacture of VRLA Battery & TSEC approved

Microtex establishes manufacture of VRLA batteries for various applications. Obtained TSEC approvals for VRLA batteries from 2V 200Ah to 2V 5000Ah in a very short time. Supplies to BSNL, Idea, Airtel, Indus Towers, Huawei, Bharti infratel, Viom, etc

Apr, 2006

Dr Rusch, leading battery scientist joins Microtex

Dr Wieland Rusch, battery expert from Germany & inventor of copper stretch metal submarine batteries, joins Microtex to upgrade & bring to world class designs for the complete range of batteries including traction battery & developed the complete range of OPzS & OPzV Gel battery. Microtex was the first company to launch Gel batteries in India.

Apr, 2008

Started production of OPzS & OPzV battery

Microtex started supplies of 2V OPzS Batteries to Nuclear facilities in India & exported Gel batteries for various applications including telecom, solar energy storage

Mar, 2011

Dr McDonagh joins Microtex as CTO

Dr Michael McDonagh with his rich manufacturing experience in various leading battery companies, established strong process controls in Microtex

2021

Fast forward to today

Microtex is legendary for its high quality batteries & reputed in the battery industry for its good & ethical business practices. Microtex manufacturing plant is environment friendly, involves employees & ensures their welfare is first. Microtex is probably one of the few companies worldwide to manufacture in house, the entire battery from the lead alloys, battery containers, the grid castings, plate manufacture, assembly & testing of batteries to world class standards.

Why choose Microtex Tubular Bags?

Technical information & unique characteristics

- Very low electrical resistance

- Chemically free from any impurities that may harm your battery

- Our automatic manufacturing process ensures defect free PT Bags

- High-tenacity, multi-strand, multi-filament polyester yarns with unmatched porosity & strength

Robust construction

- Very flexible & strong - easy filling of powder or slurry

- No pin holes or defects

- Highly acid resistant

- Microtex invests years of in-house experience. Our world-renowned battery scientists and experts continuously test and improves our products. Because of this, you’ll receive a more efficient battery separator than you are likely to buy elsewhere

Here is the perfect PT Bags if you want trouble-free battery performance

Microtex Tubular Bags

pluri tubular bags bursting strength best in class

Itema High speed rapier looms - defect free fabrics

What is the cost of Tubular Bags?

Send us an inquiry, now.

Our happy battery customers

All logos belong to the respective companies & Microtex is not associated with the brands

Microtex Reputation. Highly demanding customer base

- OEM suppliers to manufacturers

- leading user manufacturing industries

- Indian Railways

- Oil companies

- Nuclear Power Corporation of India

- Exported globally

Get a quote, Now!

Established in 1969

Exporting Batteries & battery components to 43 countries since 1977!

Battery & PT Bags manufacturing plant in India

What Microtex customers experience with Microtex

Related Products

- Traction Batteries

- Golf Cart Batteries

- EV Batteries

- Semi Traction Batteries

- Mining Locomotive Batteries

- Solar Battery

- Tubular Gel Battery

- 2V Battery flooded

- OPzS Battery

- OPzS Battery

- Inverter Battery

- 12V Battery flooded

- 2V TGel Battery

- 2V AGM Battery

- 12V Gel Battery

- Railway Battery

- Diesel Locomotive Battery

- Signaling Battery

- TRD Battery

- Train Lighting Battery

Send us an inquiry, now.

Related Battery Blog Articles