Electric Multiple Unit

What is EMU in Railway? Electric Multiple Unit/Main-line Electric Multiple Unit (MEMU) train usually have one driving coach at each end. One EMU/MEMU comprises one motor coach and one trailer coach. The lengths of the 9-coach formation Electrical Multiple Unit Indian Railways train and the 12-coach formation MEMU train presently running on Indian Railways are 195 meters (approx.) and 267 meters (approx.), respectively. This is the primary train length of an Electric Multiple Unit (EMU) and MEMU train.

An EMU requires no separate locomotive

Why Microtex are considered as leading

Electric Multiple Unit (EMU) Battery Manufacturers

German Designs - Made for Indian conditions

Microtex batteries are designed by Dr Wieland Rusch a leading battery scientist & inventor of the copper stretch metal submarine battery design.

Comparable to any leading international brands of batteries – our designs match with the best in the world.

Established in 1969, Microtex is known for its legendary quality

Microtex batteries are known the world over for its dependable & reliable battery performance

Unlike competitors, Microtex makes the complete battery & all its components in house

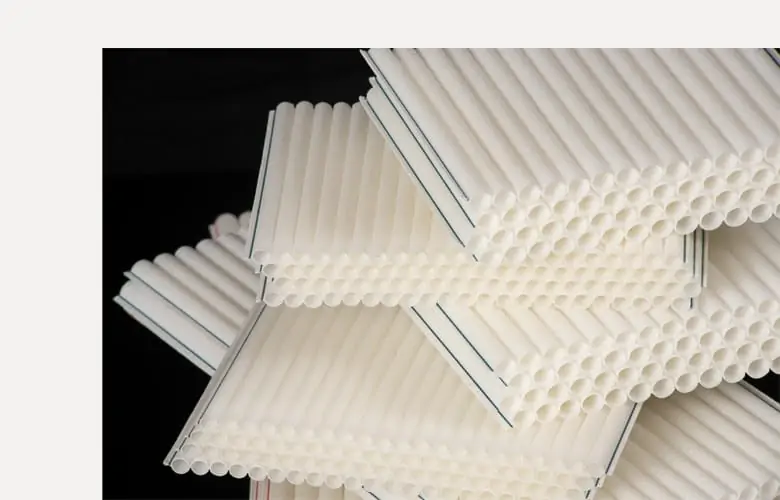

Microtex produces in house, the specially designed lead alloys, lead oxides, grid castings, pasted plates, injection-moulded containers, multi-tubular gauntlets (PT Bags), PVC separators and produces the complete battery using state of the art industry standard battery making machinery.

Designed by Dr Wieland Rusch of Germany – Manufactured with precision and pride in India, we make the complete Electric Multiple Units batteries and all its components in house ensuring a high level of quality without having to depend on outside vendors.

What are Electric Multiple Unit (EMU)?

EMU full form in Railway – Electric multiple units, are trains consisting of self-propelled carriages powered by electricity. As electric traction motors are built into one or more of the carriages in an EMU, there is no need for a separate locomotive. With their fast acceleration and pollution-free operation, EMUs are popular on commuter and suburban rail networks around the world.

Electric Multiple Units (EMU) Battery & Battery Charger

An automatic static battery charger is available onboard which is fed from an auxiliary supply and has a rating and charging characteristics suitable for the battery. It also has provision for monitoring of charging current and voltage and provision for fine adjustments and good stability to avoid overcharging or undercharging of EMU batteries. Low maintenance batteries of adequate capacity (C5 capacity) are provided on EMU and MEMU. The nominal voltage of the battery is 110V. The batteries is maintained at an adequate level of charge to satisfy the requirements as below:

- System maintained time

- Emergency ventilation 90 minutes after the loss of OHE power

- The communication system (PIS and PA system)

- 4 hours after the loss of OHE power

- Emergency lighting 4 hours after the loss of OHE power

- Door release of alternate doors on either side

- 4 hours after the loss of OHE power

- Train controls (full load) 4 hours after the loss of OHE power

- Fire detection system 4 hours after the loss of OHE power

Electric Multiple Units (EMU) battery suppliers

Microtex offers the RDSO approved 10V 90Ah Electric Multiple Unit batteries in tubular plates technology, meeting & exceeding RDSO standards. Only tubular plate batteries can offer true deep cycle performance. Read all about tubular plate technology in this link.

Microtex have been manufacturing & exporting batteries from 1977.

52 years of manufacturing experience puts our Electric Multiple Units batteries as one of the top 10 EMU battery manufacturers. Designed for deep discharge performance, it is manufactured with special antimony alloys, requiring very less water topping-up. A boon for the Indian Electric Multiple Units Battery maintenance team!

Microtex Railway Electric Multiple Units battery is made from completely formed plates; & not green plates, formed after assembly.

This is to eliminate any chance of unformed active material in the electrodes.

With Microtex Railway Electric Multiple Units batteries, you get:

- Trouble-free performance

- Reduced water topping-up needs, makes you feel it is a waterless battery!

- Faster charge acceptance with nano-carbons!

- High power efficiency – performs through the fairway!

- Longer discharge period – heavy-duty, coupled with deep-cycle capabilities

- Long-life – better return on investment

The TRUTH about how To Choose a Dependable Railway Electric Multiple Unit Batteries...

even if You Have Been Told All Railway EMU Batteries Are Plus Or Minus The Same Thing!

This is to certify that Traction Battery type 48v 470Ah supply by you in the year 2008 is working in Good Condition and Performance is satisfactory. We are getting good service support from Microtex.

2-7-2019: Woory Automotive India Pvt Ltd - Tamil Nadu Tweet

This is to certify that Traction Battery type 36v 756Ah supply by you in the years 2012 and 2018 is working in Good condition and performance is satisfactory. Both batteries are fixed in Crown Reach Truck. We are getting good service support from Microtex. Snowfield Cold Storage - Tamil Nadu

25-1-2020: Snowfield Cold Storage - Tamil Nadu Tweet

At Microtex we believe our customers must get the best Railway Electric Multiple Units battery performance & life consistently. To this end, we leave no stone un-turned to ensure that you get a superior battery built with great care & passion.

Key Features of EMU Batteries

- Designer Low antimony-tin-selenium lead alloys ensure the need for frequent water topping up is substantially reduced – a blessing for the Railway Electric Multiple Units battery maintenance

- Reduced Maintenance requirements: due to the very low antimony design with selenium as grain refiners, the need to top-up frequently is vastly reduced

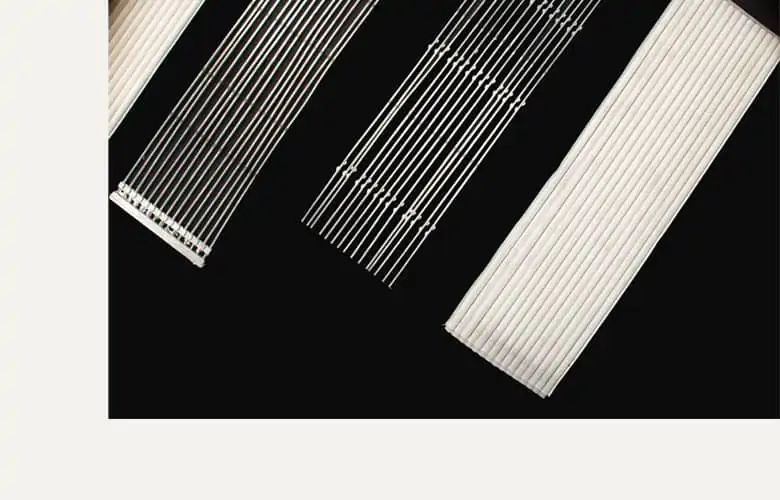

- Microtex Electric Multiple Units batteries are supplied only with woven tubular bags we do not use nonwovens

- Self-discharge: Approx 2-15% per month depending on storage temperature conditions

- Recovery after deep discharge: Very good

- Operational temperature: -20°C to 45°C, recommended 10°C to 35°C, short time 45°C to 55°C

- Microtex grid technology is an alloy of lead, tin, and antimony specifically formulated for use with Microtex NanoPlus Paste with Carbon Technology. The grid formulation provides outstanding structural adhesion between NanoPlus Active Material Paste and the grid frame.

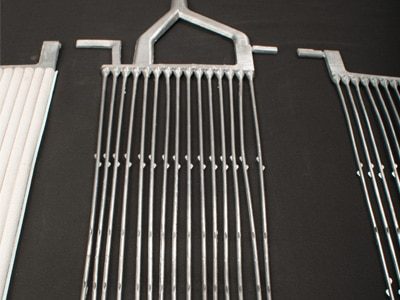

- Thick high pressure die casted grids at an incredible 150 bar pressure, creates a robust spine grid with reduced corrosion, resulting in enhanced battery performance, longer life, reducing maintenance costs and downtime.

Made in India with German Technology

- Railway Electric Multiple Units Heavy-duty Battery Terminal Connectors designed for the rated capacity without causing terminal melting or connector melting (common failure mode during service)

- High-quality hardened lead alloys used in terminals & connectors, also with brass inserts

- Trouble-free battery performance throughout its 4 year expected life

- A dedicated support team for customer service to help you with the Railway Electric Multiple Units battery replacement

- German Design: With balanced active materials delivers Electric Multiple Units battery capacity that meets international specifications

- Durability: Robust heavy-duty construction, thicker spines, coupled with deep-discharge performance

- Price: A realistic, and competitive Railway Electric Multiple Units battery price

- Delivery: fastest 21 days assured on time delivery, every time; Guaranteed

- After-sales: A fully committed, PAN India customer care service is available a phone call away to solve any Railway Electric Multiple Units battery maintenance issue quickly and efficiently

If you need Electric Multiple Units (EMU) battery Price

Send us an inquiry, Now!

Microtex Railway Electric Multiple Units Battery Specifications

Microtex offers a heavy duty deep-cycle railway Electric Multiple Units battery in PPCP Containers. All Microtex batteries are approved by RDSO as per the latest specifications.

- Microtex Make 10v 90Ah

- Type of EMU battery – Monobloc

- Manufacturers nomenclature: 10V90PLM

- Battery container material: Polypropylene Co-polymer (PPCP)

Microtex Railway Electric Multiple Units batteries are available ex stock. Quantities of 100 EMU batteries & above are usually delivered in 21 days

- Railway Electric Multiple Units batteries are dispatched in full lorry loads/small trucks , secured well & is packed suitably for safe transport.

- Microtex ensures safe delivery

- All batteries come with our standard 1 year warranty

Technical Data

Note :

H – Height is upto Terminal

PPCP – Polypropylene Co-polymer

All Batteries are supplied in dry uncharged condition

The electrical characteristics are nominal indicative values and can vary within ±5.0%.

For all batteries in Dry and Uncharged condition the initial filling and charging is to be carried out as per the technical parameters & instructions mentioned in the user manual:

| Overall Dimension in mm | Battery Weight (appx.) Kgs. | ||||||

| Battery Type | Material Of Container /Lid | Capacity in Ah at 270C 10Hr | L +5 mm | W +5 mm | H +5mm | Without Electrolyte | With Electrolyte |

| Mi 10 90 LM | PPCP | 90 | 356 | 220 | 365 | 27.03 | 42.00 |

Microtex Electric Locomotive batteries meet stringent RDSO Standards and meets electrical performance to comply with:

- RDSO Specification RDSO/PE/EMU/SPEC/0014-2000 Rev 0 Amdt 1 & 2

Microtex have been supplying locomotive engine starter batteries to the Indian Railways since 1994 & is a highly respected battery.

Our labs are equipped with state-of-the-art high-quality life-cycle testers from world-class suppliers Bitrode and Digatron to ensure our batteries stand meet the required electrical parameters to the test of time.

- The discharge shall commence not less than 12 hrs. and not more than 24 hrs. from the completion of a full charge and the battery unit shall be discharged through a suitable resistance at a current I = 0.1xC10 ampere. C10 being the rated capacity. The discharge shall be stopped when the closed-circuit voltage across the terminals falls to 1.80 x n volts, where ‘n’ is the number of cells in series or until the voltage across one cell has fallen down to 1.75 volts.

- At this rate of discharge hourly readings may be taken until the battery unit voltage approaches 1.80V x n volts after which the readings shall be taken every 15 min.

- Two more discharge tests shall be carried out in accordance with Srl No 1 and the result of the test giving maximum AH capacity shall be taken as the 10 hrs. capacity.

- The battery unit shall be charged at a rate recommended by the manufacturer, immediately after each discharge.

- The capacity in ampere hours shall be obtained by multiplying the discharge current by the total time of discharge in hours and the product so obtained shall be corrected to a temperature of 27 deg. C by the following formula:

Ct

C27 = ————-

1 + R(t-27)

Where C 27 = Capacity at 27 deg. C

C t= Observed capacity at t deg. C

t = Average room temp. in deg. C

R = 0.0043 for 10 hr. rate of discharge.

The following method shall be used for determining the maximum ampere hour and watt-hour efficiencies.

- Ampere hour efficiency: A fully charged battery unit shall be discharged at I = 0.1 x C 10 ampere to a voltage

of 1.80 x n volts, careful measurements being made of the exact number of ampere hours delivered. On the charge the same number of ampere hours are put back at the same current. A second discharge shall then be made to the same cut off voltage as before. The efficiency of the battery unit is then calculated as the ratio of the ampere hour delivered during the second discharge corrected to the ampere hour put in during the charge. - Watt hour efficiency: The watt hour efficiency shall be calculated by multiplying the ampere hour efficiency by the ratio of average discharge and recharge voltages shall be calculated from the log sheets for ampere hour efficiency.

- Ampere-hour and watt hour efficiencies shall be not less than 95% and 80% respectively.

- The battery unit shall be charged at the normal charging rate. After charging, the battery unit shall be discharged for one hour at 10 hr. rate.

- The test shall be continued by increasing the discharge current to approx. equal to 1.5 times the value specified in Col.10 in Appendix-C (A1) and after an interval not exceeding 5 min., the current shall be decreased to half the value specified in Col.10 of Appendix-C (A2). The current A1 and A2 in amperes and the corresponding battery unit terminal voltages V1 and V2 in volts, shall be measured simultaneously.

The internal resistance expressed in milli-ohm of the battery unit under test shall be calculated from the formula given below:

(V2-V1)1000

R = —————–milli ohm

(A1-A2)

The internal resistance may also be measured by a direct reading meter of agreed to between the manufacturer and the purchaser.

The internal resistance when measured shall not be more than the value specified as for the respective class of diesel locomotives.

Please click to view certificate

- Microtex Electric Multiple Units batteries are supplied suitably packed for distant transport within India or in sea worthy pallets for exports.

- Instruction & maintenance manual

- Charging manual & user record book

- Peace of mind with our dedicated all India service support

Often taken for granted until things go wrong, batteries require some small maintenance and care. Electric Multiple Units Batteries are composed of lead-acid cells, which need an equalizing charge once a year to prevent capacity loss and to bring up all the cells up to the same voltage. Leave this to the battery experts at Microtex

We shall be happy to maintain your Electric Multiple Units battery at Railway sites and help protect your equipment. Call us now & inquire about our friendly service package for your Electric Multiple Units batteries +91 9686 448899

Please provide us with the following information to ensure that you receive the right product for years of great performance:

- What is the required battery quantity

- Contact us

Please click the link below to view:

Industry-leading European Battery Experts work with us

The best experts from the European battery, industry assist in the design of Microtex Railway Electric Multiple Units battery & Processes to European Standards – Making us the preferred Electric Multiple Units Batteries Suppliers to the Indian Railways!

Microtex have been manufacturing & exporting batteries from 1977!

Microtex timeline

May, 1969

Established as mfrs of PVC Battery Separators & PT Bags

Mr A Govindan our Founder & first generation entrepreneur, establishes Microtex pioneering the manufacture of battery separators & Tubular Bags which were import substitutes at the time. He obtained a patent for the Pluri Tubular Bags in 1975

Feb, 1977

Started exporting Traction Batteries to USSR

Not many companies in the world have the rich experience of manufacturing & exporting traction batteries from 1977. Microtex have supplied over 4500 traction batteries a year during the period

March, 1985

Approved for supply of 2V batteries for Telecom

Started supplies of 2V flooded LMLA batteries to the state owned P&T

April, 1994

Approved for supply to Indian Railways

Batteries for rolling stock applications & stationary batteries for signaling applications.

July, 2003

launched INtelliBATT 12v TT inverter batteries

Highly successful Microtex 12V flooded batteries for the huge inverter battery markets

Feb, 2005

Started manufacture of VRLA Battery & TSEC approved

Microtex establishes manufacture of VRLA batteries for various applications. Obtained TSEC approvals for VRLA batteries from 2V 200Ah to 2V 5000Ah in a very short time. Supplies to BSNL, Idea, Airtel, Indus Towers, Huawei, Bharti infratel, Viom, etc

Apr, 2006

Dr Rusch, leading battery scientist joins Microtex

Dr Wieland Rusch, battery expert from Germany & inventor of copper stretch metal submarine batteries, joins Microtex to upgrade & bring to world class designs for the complete range of batteries including traction battery & developed the complete range of OPzS & OPzV Gel battery. Microtex was the first company to launch Gel batteries in India.

Apr, 2008

Started production of OPzS & OPzV battery

Microtex started supplies of 2V OPzS Batteries to Nuclear facilities in India & exported Gel batteries for various applications including telecom, solar energy storage

Mar, 2011

Dr McDonagh joins Microtex as CTO

Dr Michael McDonagh with his rich manufacturing experience in various leading battery companies, established strong process controls in Microtex

2021

Fast forward to today

Microtex is legendary for its high quality batteries & reputed in the battery industry for its good & ethical business practices. Microtex manufacturing plant is environment friendly, involves employees & ensures their welfare is first. Microtex is probably one of the few companies worldwide to manufacture in house, the entire battery from the lead alloys, battery containers, the grid castings, plate manufacture, assembly & testing of batteries to world class standards.

Why choose a Microtex Electric Multiple Units Batteries?

Technical information & unique characteristics

- Robust Polypropylene Co Polymer (PPCP) container & lid

- Unique flame-proof design ceramic vent plug with visual float level indicator for easy checking of acid level without opening each plug

- Designer lead alloys with low antimony, tin, selenium, arsenic for positive electrodes & special additives for negative electrodes to prevent failure due to corrosion

- Lower antimony ensures lesser water topping up requirements. With a Microtex Electric Multiple Units battery it feels like a water less battery

- Accurately balanced active materials ensure overcharge tolerance giving you long life & trouble free performance

- Cured & formation processed plates - ensures high-quality

- Superior Woven Tubular Gauntlets (not NONWovens) for tubular electrodes. Woven tubular gauntlets will not rupture in service and active material will not leak causing internal shorts & failure

- High-quality electrolytic grade lead coated copper intercell connectors

Robust construction

- Thicker spine grids & busbar ensure better compaction of lead, can withstand corrosion & provides longer life

- Incredible 150 Bar pressure die casted spine grids for positive tubular electrodes (densely compacted under such high pressures prevent early corrosion failures)

- Poly Propylene copolymer (PPCP) container specially designed for a hermetically strong bonded heat sealing of container to lid

- Special Tin coated copper inserts in terminal posts for faster current conductivity

- Factory formed Batteries – Quick initial charge, saves time

- Microtex invests years of in-house experience. Our world-renowned battery scientists and experts continuously test and improves our products. Because of this, you’ll receive a more efficient battery than you are likely to buy elsewhere

You get -

- The complete RDSO approved Electric Multiple Units battery range available

- Tubular battery design ensures deep cycle capabilities

- High capacity tubular battery with deep discharge characteristics recovers from deep cycles quickly

- Trouble-free performance

- Delivers the rated capacity

- We ensure our Railway Electric Multiple Units battery price is among the most competitive in the industry

with more benefits for you

- Long service life - Best return on investment costs

- Low water consumption – less frequent maintenance – very low maintenance costs

- Excellent Reserve Capacity- Designed to sustain PSoC up to six months

- Higher charge efficiency = ampere-hour efficiency of over 90%

- Deep-discharge capabilities with higher charge efficiency = ampere hour efficiency of over 90%

- All India service network

Special unique features & benefits of Microtex Electric Multiple Units Batteries

Special Patented alloys for ULM

Ultra Low Maintenance characteristics. Microtex uses very low antimony selenium tin lead alloys to ensure water consumption is minimum. Reducing the need for frequent water topping up. Feels like a water less battery!

Woven Pluri-Tubular Bags

Microtex only uses the higher quality woven PT Bags (NOT Nonwoven like in teabags). Made from high-tenacity, multi-strand, multi-filament polyester yarns treated with acrylic resins for high acid-resistance & oxidation resistance. The plate will not rupture during service!

Incredible 150 Bar Rusch Spine Grid

The spine grids for the tubular plate electrodes are cast on ultra-modern pressure die casting machines. Lead is compacted densely into the spines under these high pressures. Keeps the heavy duty grids corrosion-free

99.985% Purity Lead

Every lot of High purity of lead, is tested in-house for purity with Spark Emission Spectrophotometer. Ensures very long life battery performance. Presence of impurities like, Ferrous, Zinc, Manganese, Nickel, Cadmium, etc harm the battery. If untested it can harm the battery causing ealry failures.

Nano-Carbon Paste formula

Microtex special paste formula incorporating nano-carbon additives with graphite ensures quick recharge due to higher charge acceptance rates. This gives it superior high-rate power C5 power ratings & minimizes charging time.

Amazing 127-points quality check

Our batteries go through 127 check points before the battery reaches you. Our stringent ISO systems & process controls ensure that you get a trustworthy, reliable & dependable battery. Resulting in increased uptime with higher productivity. Highest cyclic endurance & best in class gravimetric energy density.

Here is the perfect solution if you want

trouble-free Electric Multiple Units battery performance

Electric Multiple Units battery life

Choose long-lasting deep-cycle tubular batteries from Microtex. Dependable lead acid battery capacity so you can get the complete performance of over 4 years. Your return on investment in Microtex Electric Multiple Units batteries is assured with the high performance & long life!

How long do Railway Electric Multiple Units batteries last?

Special designer lead alloys, with super additives, tin, low-antimony, arsenic, ensuring a really long life for your Microtex Railway EMU battery. In addition, we add nucleating agents like selenium, sulfur & copper to ensure the lead electrodes do not corrode for a long time, ensuring a very long life. The addition of nucleating agents gives the grids a fine-grained structure with good corrosion resistance as otherwise, the coarse dendritic structure will be prone to hot cracking and porosity.

Microtex Railway Electric Multiple Units Batteries

How much does an Electric Multiple Unit battery cost?

Send us an inquiry, now.

Our happy customers

All logos belong to the respective companies & Microtex is not associated with the brands

Microtex Reputation. Highly demanding customer base

- OEM suppliers to manufacturers

- leading user manufacturing industries

- Indian Railways

- Oil companies

- Nuclear Power Corporation of India

- Exported globally

Get a quote, Now!

Established in 1969

Exporting Batteries to 43 countries since 1977!

Battery manufacturing plant in India

What Microtex customers experience

Related Batteries

- Railway Battery

- Diesel Locomotive Battery

- Signaling Battery

- TRD Battery

- Train Lighting Battery

Send us an inquiry, now.

Related Battery Blog Articles

Battery Mistakes All Electric Multiple Units battery Owners Need To Avoid!

Do not mix new batteries with old batteries

Railway Electric Multiple Units Battery reconditioning: often reconditioning an old EMU battery can become quite a costly affair if you keep replacing dead batteries one by one; even the new battery will drain out rapidly as the old batteries tend to draw more out of the new one.

Electric Multiple Units replacement batteries: It is best to have an expert from the company visit you to have a thorough inspection of the Electric Multiple Units batteries after a complete charge, compare the cell voltage, specific gravity to decide the state of charge & whether in needs to be replaced at all.

Avoid any sort of additives or desulfation methods

How to recondition Electric Multiple Units batteries? MEMU Batteries are electro-chemical devices. All chemicals have a half-life period beyond which regeneration with chemical additives or desulfators for batteries have little effect if any temporary.

The normal mode of failure of Electric EMU batteries is usually due to grid corrosion if the lead alloys are not designed properly. Desulfators cannot repair corroded grids.