OPzV BATTERY

2v OPzV Battery made in India

Microtex is a leading OPzV battery manufacturer in India, supplying high-performance 2V OPzV tubular gel batteries for critical industrial and energy storage applications. Designed for long service life, deep-cycle endurance, and high-temperature stability, Microtex OPzV batteries are widely deployed across solar power plants, telecom networks, utilities, substations, oil & gas facilities, and industrial backup systems.

Our OPzV tubular gel battery range combines German design principles with robust Indian manufacturing, delivering consistent performance under demanding operating conditions. With proven field installations and compliance to international standards, Microtex OPzV batteries are widely recognized as one of the best OPzV battery solutions for solar and stationary energy storage.

Available in a full range of capacities, our batteries are engineered with optimized gel formulation, tubular positive plates, and reinforced containers to ensure predictable life, low maintenance, and dependable backup. Detailed OPzV battery specifications, sizing support, and technical documentation are available on request to support EPCs, system integrators, and project consultants.

First company in India to launch OPzV in 2008!

The deep-cycle tubular gel 2V OPzV battery design incorporates precision-engineered German vent valves and a fully sealed construction, eliminating the need for water topping and removing any risk of acid spillage. These batteries support both vertical and horizontal installation, providing flexibility in rack and enclosure design.

Optimized active material formulation enables faster charge acceptance and higher recharge efficiency, while the immobilized gel electrolyte prevents acid stratification and mitigates premature failures caused by Partial State of Charge (PSoC) operation. This makes Microtex OPzV batteries a preferred choice for solar energy storage and critical standby applications where reliability and lifecycle cost are decisive.

2V OPzV Battery Manufacturer in India for Solar & Critical Power Applications

For Solar Power, Electricity Generation, Nuclear, Telecom, BESS & Standby Power

Microtex is a trusted 2V OPzV battery manufacturer in India, supplying industrial-grade OPzV tubular gel batteriesengineered for deep-cycle operation and long-duration float service. Our 2V OPzV cells in ABS containers are specifically designed for demanding applications such as solar off-grid systems, electricity power generation, nuclear facilities, telecommunications networks, BESS installations, offshore oil rigs, and standby power systems.

Each OPzV battery is manufactured using advanced tubular plate technology, controlled gel electrolyte formulation, and stringent in-process testing to ensure predictable life and consistent performance. The robust ABS plastic containersretain structural integrity across a wide operating temperature range of −20°C to +55°C, making them suitable for harsh climatic and high-temperature environments.

Request OPzV Battery Specifications & Pricing

Talk to a Battery Application Engineer

Understanding OPzV Batteries

What is OPzV battery?

An OPzV battery is a stationary valve-regulated lead-acid (VRLA) battery that combines tubular positive plate construction with a gelled electrolyte system. The designation “OPzV” originates from the German term Ortsfest Panzerplatte verschlossen, meaning sealed stationary tubular plate battery.

Designed specifically for long-duration standby and deep-cycle operation, 2V OPzV batteries are widely used in solar energy storage, telecom backup, utilities, substations, and other critical power applications. Their sealed construction, predictable performance, and long design life make OPzV batteries a preferred choice where reliability and low lifecycle cost are essential.

Key Features of OPzV Batteries

- Tubular Plate Design

OPzV batteries use tubular positive plates, where the active material is held within woven polyester tubes. This construction improves mechanical strength, reduces active material shedding, and supports long cycle life under deep discharge and float conditions.

Gel Electrolyte

The gelled electrolyte immobilizes sulphuric acid, eliminating stratification and enabling uniform electrochemical reactions. This design supports operation in high-temperature environments and prevents failures associated with Partial State of Charge (PSoC) conditions.

Maintenance-Free Operation

As a sealed VRLA design, OPzV tubular gel batteries do not require water topping. This reduces routine maintenance, minimizes human intervention, and lowers operating costs over the battery’s service life.

Long Service Life

OPzV batteries are engineered for extended float and cyclic life, making them a cost-effective solution for long-term stationary installations. Their stable performance profile supports predictable replacement planning for EPCs and utilities.

Deep Discharge Capability

2V OPzV batteries are designed to withstand repeated deep discharge cycles without rapid degradation. This makes them suitable for solar off-grid systems, renewable energy storage, and applications with frequent discharge events.

Enhanced Operational Safety

The sealed construction and gel electrolyte significantly reduce the risk of acid leakage and excessive gas emissions. Precision vent valves regulate internal pressure, ensuring safe operation in enclosed battery rooms and racks.

Applications of OPzV Batteries

OPzV batteries are purpose-built for stationary energy storage and critical power backup applications where long service life, deep discharge capability, and operational reliability are mandatory. Due to their tubular plate design and gel electrolyte system, 2V OPzV batteries are widely deployed across renewable energy, telecom, utilities, and industrial infrastructure.

Renewable Energy Storage – Solar Off-Grid Systems

OPzV tubular gel batteries are widely regarded as one of the best OPzV battery solutions for solar energy storage, particularly in off-grid and hybrid systems. Their high cycle endurance and deep discharge tolerance allow reliable storage of excess solar energy generated during peak sunlight hours. The stored energy is released during nighttime or low-generation periods, ensuring consistent power availability. These characteristics make OPzV batteries suitable for remote solar installations, microgrids, and renewable energy projects operating under variable load conditions.

Telecom Backup Power

Telecommunication infrastructure requires uninterrupted power to maintain network availability and service continuity. OPzV batteries are commonly used as backup power sources for telecom towers, MSC sites, switching centers, and data centers. Their sealed, maintenance-free construction and long float life reduce operational interventions while ensuring dependable backup during grid outages. For telecom operators, 2V OPzV batteries offer predictable performance, lower lifecycle costs, and high reliability in both urban and remote deployments.

Industrial Applications

Industrial facilities rely on robust power systems to protect critical processes and automation. OPzV batteries are used for backup power in manufacturing plants, control rooms, substations, emergency lighting systems, and automated machinery. Their ability to operate under high discharge rates, elevated temperatures, and demanding environmental conditions makes them suitable for industrial standby applications. The tubular gel design ensures stable performance even during repeated discharge events and extended standby operation.

Grid Stabilization and Utility Support

OPzV batteries support grid stabilization by storing excess energy during low-demand periods and supplying power during peak demand. Utilities and power distribution networks use OPzV battery banks to improve grid reliability, manage load fluctuations, and reduce the risk of outages. Their long design life and consistent charge acceptance make them suitable for stationary utility-scale energy storage and substation backup applications.

Emergency Power Supply

In emergency scenarios such as grid failures, natural disasters, or infrastructure shutdowns, reliable backup power is critical. OPzV batteries are deployed in emergency power systems for hospitals, emergency response centers, public safety facilities, and essential services. Their deep discharge capability, long service life, and low maintenance requirements ensure dependable power availability when it is needed most.

Why Choose Microtex OPzV Batteries?

Selecting the right OPzV battery is critical for long-term system reliability, lifecycle cost control, and operational safety. Microtex combines proven field performance, advanced tubular gel technology, and rigorous manufacturing discipline to deliver 2V OPzV batteries trusted across solar, telecom, utilities, and industrial infrastructure.

Proven Reliability in Critical Applications

Microtex has a long-standing track record as an OPzV battery manufacturer in India, supplying batteries for mission-critical applications where failure is not an option. Our OPzV batteries are engineered for consistent performance under deep-cycle and float conditions, ensuring dependable backup and energy storage across varied operating environments.

Advanced Tubular Gel Battery Technology

Microtex OPzV tubular gel batteries are manufactured using advanced tubular plate construction, optimized gel electrolyte formulation, and precision venting systems. This technology delivers high charge acceptance, resistance to acid stratification, and stable performance under Partial State of Charge (PSoC) operation. The result is predictable performance and extended service life in demanding stationary applications.

Stringent Quality Control and Testing

Every 2V OPzV battery undergoes stringent quality control at each stage of manufacturing. From raw material inspection to in-process checks and final electrical testing, Microtex follows disciplined testing protocols to ensure compliance with performance, safety, and durability requirements. This controlled approach reduces early-life failures and supports long-term reliability in field installations.

Technical Expertise and Application Support

Microtex provides direct access to experienced technical teams for OPzV battery selection, sizing, installation guidance, and lifecycle support. Whether the requirement involves solar energy storage, telecom backup, or utility-scale installations, our engineers support EPCs, consultants, and operators with application-specific recommendations and documentation.

Sustainable and Responsible Manufacturing

Microtex is committed to environmentally responsible manufacturing practices. Our OPzV batteries are designed for long service life, reduced maintenance intervention, and recyclability at end of life. This approach supports sustainability goals while delivering reliable energy storage solutions for critical infrastructure.

What sets our OPzV cell apart from the rest?

Microtex OPzV tubular gel batteries are engineered for long-life stationary energy storage, combining German design principles with robust Indian manufacturing. Our 2V OPzV battery range is designed to deliver predictable performance, deep-cycle endurance, and low lifecycle cost across solar, utility, telecom, and industrial applications.

Complete International OPzV Capacity Range

Microtex offers a full, internationally accepted range of 2V OPzV batteries, from 238Ah to 3337Ah, supporting flexible battery bank design for small to large installations. Popular models such as 4 OPzV 200, 6 OPzV 300, 6 OPzV 600, 8 OPzV 800, and 10 OPzV 1000 are widely deployed in solar energy storage systems and are among our most proven configurations for off-grid and hybrid solar projects.

Long Operational Life and Cycle Performance

Microtex OPzV cells are designed for an operational life exceeding 20 years in standby float service at 25°C. The batteries deliver more than 1800 cycles as per IEC 60896-2, with excellent recovery after deep discharge. Low self-discharge of approximately 2% per month at 25°C ensures energy retention during extended standby periods.

Maintenance-Free and High-Temperature Tolerant Design

As sealed OPzV tubular gel batteries, Microtex cells require no water topping throughout their operational life. They are designed to operate reliably across a wide temperature range from −20°C to 45°C, with short-term tolerance up to 55°C. The recommended operating range of 10°C to 35°C supports optimal service life in stationary installations.

Standards Compliance and Design Classification

Microtex OPzV tubular gel batteries are engineered in line with IEC 60896-2 requirements for stationary valve-regulated lead-acid batteries and follow Eurobat long-life design classification principles. The batteries are designed for extended float service, high cycle endurance, and stable operation under deep discharge and Partial State of Charge conditions. This standards-driven design approach ensures predictable performance, long service life, and suitability for critical infrastructure such as solar power plants, utilities, substations, telecom networks, and industrial standby systems.

Reliability and German Design Engineering

Microtex OPzV batteries are developed using German design philosophy, with balanced active material formulation to deliver rated capacity in line with international specifications. The tubular plate construction and gel electrolyte ensure consistent backup duration during power outages, providing confidence that the OPzV cell power supply remains stable when it matters most.

Robust Construction and Competitive Lifecycle Cost

Heavy-duty internal construction, reinforced containers, and deep-discharge capability make Microtex OPzV cells suitable for demanding operating environments. While designed to international performance benchmarks, our OPzV tubular gel battery pricing remains realistic and competitive, delivering strong value over the battery’s full lifecycle rather than just initial cost.

Made in India with German Technology

Microtex OPzV batteries are engineered in India using proven German design and material science, combining global performance standards with reliable domestic manufacturing. This approach ensures long service life, consistent quality, and suitability for demanding stationary energy storage and backup power applications.

Smart Terminal Pole Bushing Design

Microtex OPzV cells feature a smart terminal pole bushing that accommodates gradual upward growth and movement of the terminal post over time. This design mitigates terminal breakage, a common failure mode observed after the seventh year of service in conventional OPzV batteries, significantly improving long-term reliability.

Advanced Gel and Grid Technology

High-quality thixotropic silica gel ensures electrolyte stability and prevents dry-out over the battery’s operational life. Calcium lead alloy grids deliver excellent oxygen recombination efficiency, supporting fully maintenance-free operation. This combination enables stable electrochemical performance under float and cyclic conditions.

Optimized Plate Alloys for Long Life

Microtex uses a carefully engineered combination of tin-calcium lead alloy tubular positive plates and lead-selenium low-antimony alloys. This alloy system represents one of the most advanced configurations in lead-acid plate technology, delivering enhanced corrosion resistance, high cycle endurance, and ultra-long service life.

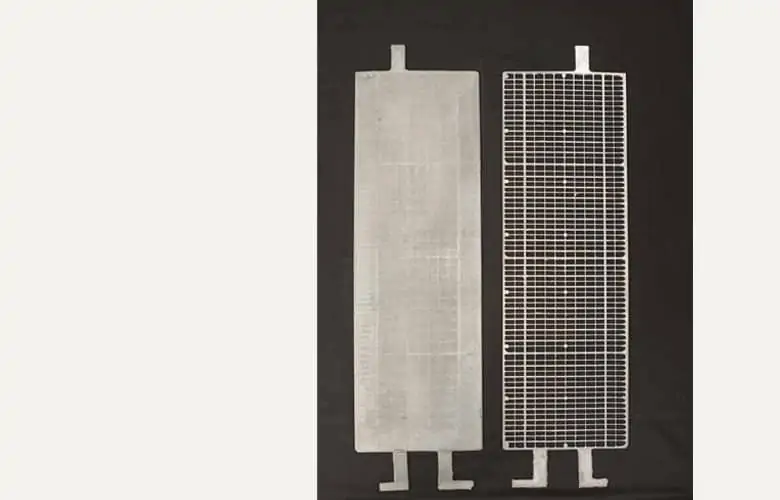

Woven Tubular Bag Construction

All Microtex OPzV tubular gel batteries are manufactured exclusively using woven tubular bags. Non-woven alternatives are not used, as woven structures provide superior active material retention, mechanical strength, and long-term cycling stability under deep discharge conditions.

Engineering Support and Export Provenance

A dedicated in-house design and application engineering team supports customers with OPzV battery selection, sizing, and system optimization. Microtex 2V OPzV batteries have been exported globally since 2007, reflecting proven acceptance across international markets and operating conditions.

Seismic-Qualified Installation Options

For critical infrastructure and high-risk zones, seismically qualified battery racks are available to support compliance with project-specific safety and structural requirements.

“Unlike generic VRLA gel batteries, OPzV tubular gel batteries with woven gauntlets and calcium-tin alloy grids are designed for deep-cycle and long float operation without early corrosion or stratification failures.”

On-Time Delivery and PAN-India After-Sales Support

Microtex maintains a strong record of on-time delivery, helping EPCs, utilities, and project developers adhere to critical commissioning schedules. Our structured production planning and logistics coordination reduce project risk and avoid delays during installation and system integration.

A dedicated PAN-India after-sales and technical support team provides assistance with OPzV battery installation, commissioning, performance monitoring, and operational queries. This ensures faster issue resolution, reliable system uptime, and long-term confidence in Microtex 2V OPzV battery installations across diverse operating environments.

Long Operational Life and Cycle Performance

Microtex OPzV cells are engineered for an operational life exceeding 20 years in standby float service at 25°C, making them suitable for long-term stationary installations. The batteries deliver more than 1800 charge–discharge cycles as per IEC 60896-2, with excellent recovery after deep discharge events. A low self-discharge rate of approximately 2% per month at 25°C ensures effective energy retention during extended standby periods, supporting reliable backup power availability.

Maintenance-Free and High-Temperature Tolerant Design

As sealed OPzV tubular gel batteries, Microtex cells require no water topping throughout their service life, reducing maintenance intervention and operating costs. The batteries are designed to operate reliably across a wide temperature range of −20°C to 45°C, with short-term tolerance up to 55°C. For optimal performance and maximum service life, the recommended operating temperature range is 10°C to 35°C, making these batteries suitable for high-temperature and uncontrolled environments.

Microtex is the first company to launch the OPzV Gel Technology in India in 2008!

Pioneer of OPzV Gel Technology in India

Microtex was the first Indian manufacturers to introduce OPzV gel battery technology in 2008, marking an early commitment to advanced tubular gel energy storage solutions. This early adoption enabled Microtex to build long-term expertise in OPzV battery design, manufacturing, and field performance, well ahead of widespread market adoption in India.

Over the years, this experience has translated into refined processes, proven reliability, and continuous product improvement across the 2V OPzV tubular gel battery range supplied to domestic and international projects.

Request a quote, now

Microtex 2V OPzV Battery datasheet, technical information, & downloads

Microtex OPzV batteries are available in the complete internationally approved range from 2v 238Ah to 2v 3337Ah in ABS containers & ABS covers

| Positive plate | Tubular plate with special calcium tin alloy |

| Negative plate | Flat pasted with nanocarbons & special additives |

| Separators | Microporous PVC battery separators |

| Container | Impact-resistant Acrylonitrile Butadiene (ABS) does not bulge in service |

| Cover/lid | ABS with large visual indicators for polarity |

| Electrolyte | Sulfuric acid with a density of 1.26 kg/l, fixed as GEL by fumed silica |

| Specific gravity | 1.260SG @ 25ºC |

| Terminal pillar post | 100% gas & electrolyte-tight, sliding design with plastic coated kind of moving pole bushing with M10 brass inserts |

| Intercell connectors | Electrolytic grade lead plated copper connectors of rated capacity |

| Vent valve | Valve Regulated Vent Plugs from Germany, high precision opening & closing pressures with explosion inhibiting ceramic |

| Operating temperature | -20ºC to 55ºC optimum recommended temp is 10ºC to 30ºC |

| Depth of discharge | normally up to 80% |

| Reference temperature | 25ºC |

| Initial capacity | 100% |

| IU Characteristics | Imax without limitation |

| U=2.25 V/cell +- 1% between 10ºC and 45ºC | |

| Float current | 20-30mA/100Ah |

| Boost charge | U=2.35 to 2.40V/cell time limited |

| Charging time up to 88% | 6h with 1.5xI10 Initial current, 2.23 V/cell, which was previously discharged up to 80% C3 rate |

2V OPzV batteries are not kept in stock and are usually delivered in 60 days. We ensure that you get factory fresh batteries for your order every time.

- Each 2V OPzV cell is cushioned well and placed inside wooden crates suitable for safe transport.

- Standard 1 year for all supplies

Microtex OPzV Batteries generally conform to

- DIN 40 742 part 1,

- DIN EN 50 272-2

- IEC 60896-21, 22

Our labs are equipped with state-of-the-art high-quality life-cycle testers from world-class suppliers Bitrode and Digatron to ensure our batteries stand meet the required electrical parameters to the test of time.

Please click to view certificate

Microtex OPzV batteries were designed and developed in house by Dr Wieland Rusch, a highly reputed battery scientist from Germany. Microtex OPzV batteries are offered in sturdy ABS (Acrylonitrile Butadiene) containers in the internationally standard range @ c10 & dimensions::

| 2v 238Ah | L105 x W208 x H420mm | 19.50 kgs |

| 2v 298Ah | L126 x W208 x H420mm | 23.50 kgs |

| 2v 356Ah | L147 x W208 x H420mm | 28.00 kgs |

| 2v 427Ah | L126 x W208 x H535mm | 31.00 kgs |

| 2v 512Ah | L147 x W208 x H535mm | 36.50 kgs |

| 2v 597Ah | L168 x W208 x H535mm | 42.00 kgs |

| 2v 729Ah | L147 x W208 x H710mm | 50.00 kgs |

| 2v 972Ah | L215 x W193 x H710mm | 68.00 kgs |

| 2v 1215Ah | L215 x W235 x H710mm | 82.00 kgs |

| 2v 1463Ah | L215 x W277 x H710mm | 97.00 kgs |

| 2v 1669Ah | L215 x W277 x H855mm | 120.0 kgs |

| 2v 2225Ah | L215 x W400 x H815mm | 160.0 kgs |

| 2v 2781Ah | L215 x W490 x H815mm | 200.0 kgs |

| 2v 3337Ah | L215 x W580 x H815mm | 240.0 kgs |

- 2V OPzV Batteries are supplied in robust wooden boxes suitably packed for distant transport within India or export worthy packing

- Lead plated electrolytic grade copper inter-cell cables or connectors of rated capacity

- Inter unit jumper cables

- Cell numbers (plastic discs)

- Lead-plated passivated SS fasteners

- Suitable seismically qualified battery stand if ordered separately; available options – MS, Galvanized steel & FRP

- Acid resistant painted plywood sheet

- Rubber mat & rubber cushion between cells

- Porcelain insulators for each cell 4 numbers

- safety goggles, gloves, utility funnel, brass wire brush, sulfation protection – petroleum jelly sachet

- Spare cells if ordered

- Instruction & maintenance manual

- Charging manual & user record book

- Internal test certificate – 3rd party NABL accredited lab testing available at cost

- Peace of mind with our dedicated all India service support

- In India – one tree sapling to promote a green environment

OPzV batteries from Microtex comes with trouble free performance. Annual checking of battery voltage, pilot cell voltage & temperature, equalizing charge & visual inspection for any damages or loose connections is all the maintenance you require for these robust high performance OPzV batteries.

Often taken for granted until things go wrong, batteries require some small maintenance and care. 2V OPzV Batteries need an equalizing charge once a year to prevent capacity variation and to bring up all the cells up to the same voltage. Leave this important task to the battery experts at Microtex

Microtex will be happy to maintain your battery banks and help protect your investment. Call us to schedule a free health check up of your OPzV battery banks +91 9686 448899

If sizing of the OPzV batteries are required, we shall be happy to assist you with the correct calculations, please provide the following details:

- Total load of the system

- Total DC voltage of the system

- Number of backup hours required

- Mean ambient temperature

Please provide us with the following information to ensure that you receive the right battery for years of great performance:

- What is the system voltage & capacity of the cells

- Which specification do you need the batteries to conform to? IS spec, IEC spec or DIN spec?

- Number of cells per system/bank

- Are maintenance tools required, if yes please name the items needed

- Are stands required, If so Teak/Sal wood, mild steel, galvanised steel or FRP?

- Do you require the stands to be seismically qualified?

- Is electrolyte required for first filling or do you have access to good quality tested electrolyte?

Please click the link below to view:

Microtex have been manufacturing & exporting OPzV batteries from 2007

for various battery backup applications meeting International norms

Microtex timeline

May, 1969

Established as mfrs of PVC Battery Separators & PT Bags

Mr A Govindan our Founder & first generation entrepreneur, establishes Microtex pioneering the manufacture of battery separators & Tubular Bags which were import substitutes at the time. He obtained a patent for the Pluri Tubular Bags in 1975

Feb, 1977

Started exporting Traction Batteries to USSR

Not many companies in the world have the rich experience of manufacturing & exporting traction batteries from 1977. Microtex have supplied over 4500 traction batteries a year during the period

March, 1985

Approved for supply of 2V batteries for Telecom

Started supplies of 2V flooded LMLA batteries to the state owned P&T

April, 1994

Approved for supply to Indian Railways

Batteries for rolling stock applications & stationary batteries for signaling applications.

July, 2003

launched INtelliBATT 12v TT inverter batteries

Highly successful Microtex 12V flooded batteries for the huge inverter battery markets

Feb, 2005

Started manufacture of VRLA Battery & TSEC approved

Microtex establishes manufacture of VRLA batteries for various applications. Obtained TSEC approvals for VRLA batteries from 2V 200Ah to 2V 5000Ah in a very short time. Supplies to BSNL, Idea, Airtel, Indus Towers, Huawei, Bharti infratel, Viom, etc

Apr, 2006

Dr Rusch, leading battery scientist joins Microtex

Dr Wieland Rusch, battery expert from Germany & inventor of copper stretch metal submarine batteries, joins Microtex to upgrade & bring to world class designs for the complete range of batteries including traction battery & developed the complete range of OPzS & OPzV Gel battery. Microtex was the first company to launch Gel batteries in India.

Apr, 2008

Started production of OPzS & OPzV batteries

Microtex started supplies of 2V OPzS Batteries to Nuclear facilities in India & exported Gel batteries for various applications including telecom, solar energy storage

Mar, 2011

Dr McDonagh joins Microtex as CTO

Dr Michael McDonagh with his rich manufacturing experience in various leading battery companies, established strong process controls in Microtex

2022

Fast forward to today

Microtex is legendary for its high quality batteries & reputed in the battery industry for its good & ethical business practices. Microtex manufacturing plant is environment friendly, involves employees & ensures their welfare is first. Microtex is probably one of the few companies worldwide to manufacture in house, the entire battery from the lead alloys, battery containers, the grid castings, plate manufacture, assembly & testing of batteries to world class standards.

Why choose a Microtex 2V OPzV cell?

Microtex 2V OPzV batteries are engineered as fail-safe stationary energy storage solutions, combining German technology with decades of in-house manufacturing expertise. Every design element is focused on long service life, electrical efficiency, corrosion resistance, and predictable performance under float and deep-cycle operation.

Advanced Plate, Alloy, and Electrode Design

Microtex OPzV cells use designer lead–calcium alloys with high tin content for tubular positive plates, combined with optimized additives for negative electrodes to resist corrosion-related failures. Special electrode geometry improves current flow to the terminals, minimizing internal resistance losses. Accurately balanced active materials provide high overcharge tolerance, supporting long life and stable performance in both float and cyclic duty.

Fully Formed, Factory-Charged OPzV Cells

All 2V OPzV batteries are supplied with fully cured and formation-processed plates, ensuring complete electrochemical conversion before dispatch. Batteries are factory charged and ready for immediate installation, eliminating the need for excessive field cycling to achieve rated capacity. This is critical for EPCs and utilities operating under tight commissioning schedules.

Superior Woven Tubular Construction

Microtex OPzV batteries are manufactured exclusively using woven tubular gauntlets, not non-woven alternatives. Woven structures provide superior mechanical strength, prevent gauntlet rupture, and eliminate active material leakage that can cause internal short circuits. This construction ensures long-term cycling stability and resistance to premature failure under deep discharge conditions.

Precision Venting and Electrical Connectivity

Specially designed valve-regulated vent plugs from Germany ensure precise opening and closing at defined internal pressures. High-quality electrolytic-grade copper inter-cell connectors with adequate current-carrying capacity minimize voltage drop and heat generation. Hardened lead alloy terminal posts with brass inserts provide fast conductivity and corrosion-resistant, fail-proof connections.

Smart Terminal Pole Bushing – Fail-Safe Design

Microtex has developed a Smart Terminal Pole Bushing (patent applied for) to address a known OPzV failure mode. As plates naturally grow during service—typically noticeable after the seventh year—this design allows controlled upward movement of the terminal post without cracking the cover. Rubber grommets absorb stress, preventing terminal breakage and extending operational life.

Robust Container, Cover, and Grid Construction

OPzV cells are housed in robust ABS containers that resist bulging during service. High-impact ABS covers with large, clear polarity markings enhance installation safety. Thicker spine grids and busbars, produced using 150-bar pressure die-casting, ensure dense lead compaction, high corrosion resistance, and extended service life for tubular positive electrodes.

Seismic Safety and Installation Readiness

Microtex OPzV batteries are supplied with seismically tested and qualified floor stands, certified by national test houses. Stands feature special acid-proof coatings for long-term durability. This makes the system suitable for utilities, substations, nuclear facilities, and other critical infrastructure requiring seismic compliance.

Performance, Efficiency, and Lifecycle Benefits

The complete international OPzV range from 2V 238Ah to 2V 3337Ah is available in standard container dimensions, with a 20-year design life at 25°C. The gelled electrolyte prevents acid stratification and PSoC-related failures. Low float current—up to 65–75% lower—reduces heat generation, air-conditioning load, and electricity consumption, while delivering >90% ampere-hour charge efficiency and excellent reserve capacity.

The perfect solution if you want Maintenance-free OPzV performance

What is the cost of an OPzV battery bank?

Experience shows that 80% of 2V OPzV batteries last only 8 to 12 years.

Don’t let that happen! Choose long-lasting deep-cycle batteries from Microtex.

- Long service life – 20 years designed life – best return on investment cost

Dependable lead acid battery capacity so you can get complete performance. Your return on investment in Microtex OPzV batteries ensures the long term cost is way lower.

Why Microtex Batteries are made better?

Microtex produces the specially designed lead alloys, lead oxides, grid castings, pasted plates, injection-moulded containers, multi-tubular gauntlets, PVC separators in house, and produces the complete battery using state-of-the-art industry-standard battery making machinery. Our batteries are built with proven designs and undergo complete life cycle testing to international norms before they are offered to the market. The electrical lab is complete with high-quality LCT from world-class suppliers Bitrode and Digatron.

Fun fact for you...! What does OPzV mean? | OPzV battery full form | OPzV battery meaning

On an interesting note… OPzV Definition is derived from German words and stands for O – Ortsfest (in German means Stationary) Pz – PanZerPlate means Tubular plate (for sturdy and robust) V – Stands for Verschlossen or Closed

Microtex 2V OPzV Applications

OPzV for Nuclear Industry

Microtex have been exporting OPzV batteries from 2007

OPzV for large off-grid solar applications

Dependable Standby batteries

OPzV cells for large standby applications

When the backup is critical you need a reliable OPzV Battery for Standby power

OPzV Battery for Thermal power Industry

Deep Discharge Standby battery power systems

Installation and Maintenance

Installation Guidelines

Proper installation is crucial to ensure the optimal performance and longevity of OPzV batteries. Here are some key installation guidelines:

Site Selection: Choose a well-ventilated and temperature-controlled location for battery installation. Avoid areas with direct sunlight, extreme temperatures, or high humidity.

Battery Racks: Use suitable battery racks or cabinets to securely mount the batteries. Ensure that the racks are designed to accommodate the weight and dimensions of the batteries.

Electrical Connections: Follow the manufacturer’s instructions for making electrical connections. Use appropriate cables and connectors to ensure a secure and low-resistance connection.

Ventilation: Ensure adequate ventilation to prevent the accumulation of gases that may be released during battery operation. Install ventilation systems if necessary.

Safety Precautions: Follow safety guidelines and wear appropriate personal protective equipment (PPE) during installation. Keep the installation area free of combustible materials and ensure that fire extinguishers are readily available.

Maintenance Tips

Although OPzV batteries are maintenance-free, periodic checks can help ensure their optimal performance:

Visual Inspection: Regularly inspect the batteries for signs of damage, leakage, or corrosion. Check the terminals and connections for tightness and cleanliness.

Voltage and Temperature Monitoring: Monitor the voltage and temperature of the batteries to ensure they are operating within the specified range. Use a battery management system (BMS) for automated monitoring and alerts.

Equalization Charging: Perform equalization charging as recommended by the manufacturer to balance the charge across all cells and prevent sulfation.

Cleaning: Keep the battery surfaces clean and free of dust and debris. Use a damp cloth to wipe the battery cases and terminals.

Record Keeping: Maintain a log of battery performance and maintenance activities. Record any anomalies and take corrective actions as needed.

Industry Insights and Trends

The energy storage industry is rapidly evolving, driven by technological advancements and the increasing demand for reliable power solutions. Here are some key trends shaping the future of OPzV batteries and the broader energy storage sector:

Growing Demand for Renewable Energy

The global shift towards renewable energy sources such as solar and wind power is driving the demand for efficient energy storage solutions. OPzV batteries are well-suited for renewable energy applications due to their long cycle life and ability to handle deep discharge cycles. As the adoption of renewable energy continues to grow, the demand for high-performance OPzV batteries is expected to increase.

Technological Advancements

Advancements in battery technology are leading to the development of more efficient and reliable power solutions. Key innovations include:

Enhanced Electrolyte Formulations: Research is ongoing to develop advanced gel electrolyte formulations that improve the performance and longevity of OPzV batteries.

Improved Plate Design: Innovations in tubular plate design are enhancing the electrical conductivity and durability of OPzV batteries, resulting in better performance and longer service life.

Advanced Battery Management Systems: Modern battery management systems (BMS) provide real-time monitoring and management of battery parameters, ensuring optimal performance and safety.

Emphasis on Sustainability

Sustainability is a key focus in the battery industry, with increasing emphasis on environmentally responsible manufacturing practices and recycling programs. Manufacturers are adopting eco-friendly processes and materials to minimize the environmental impact of battery production. At Microtex, we are committed to sustainability and actively promote recycling and responsible disposal of batteries.

2V OPzV Batteries for C&I customers, off-grid solar home users, Data centres, BESS, large UPS systems, Nuclear power generation plants, Thermal power stations, Hydro-electric power plants, Electricity substation battery requirements, Large Solar off-grid systems, Oil & gas industry, Petrochemical plants, Controls & Switchgears

Send us an inquiry, now.

German Designs - Made for Indian conditions

Microtex batteries are designed by Dr Wieland Rusch a leading battery scientist & inventor of the copper stretch metal submarine battery design.

Comparable to any leading international brands of batteries – our designs match with the best in the world.

Established in 1969, Microtex is known for its legendary quality

Microtex batteries are known the world over for its dependable & reliable battery performance

Unlike competitors, Microtex makes the complete battery & all its components in house

Microtex produces in house, the specially designed lead alloys, lead oxides, grid castings, pasted plates, injection-moulded containers, multi-tubular gauntlets (PT Bags), PVC separators and produces the complete battery using state of the art industry standard battery making machinery.

Our happy customers

All logos belong to the respective companies & Microtex is not associated with the brands

Microtex Reputation. Highly demanding customer base

- Nuclear Power Corporation of India

- National Hydro Power Corporation

- Electricity substations & Power Generating Stations across India

- Indian Railways

- Oil companies

- Telecom operators

Get a quote, Now!

Established in 1969

Exporting Batteries to 43 countries since 1977!

Battery manufacturing plant in India

What Microtex customers experience

What is the difference between OpZS and OpZV batteries?

| Comparision of OPzV and OPzS | |

| OPzV cells | OPzS cells |

| Nominal 2volts per cell | Nominal 2volts per cell |

| Container Material is Acrylonitrile butadiene(ABS) | Container Material is Styrene acrylonitrile (SAN) |

| Positive plate Alloy is made from Calcium Plus | Positive plate Alloy is made from Calcium Plus |

| Container is Opaque | Container is Transparent |

| Electrolyte is gellified with thixotropic silica – level is not visible | Liquid Electrolyte – level is Visible |

| Plates in the cell are not visible | Plates in the cell are visible for monitoring towards end of life |

| Maintenance free no Topping up with water | Topping up required with DM water intervals 1-3 years |

| The Plates are DIN design ie width of 198mm | The Plates are DIN design ie width of 198mm |

| Special terminal bush design will allow to move the positive terminal pole growth movement and keeps 100% seal against acid and gases | Special terminal bush design will allow to move the positive terminal pole growth movement and keeps 100% seal against acid and gases |

| Cells can be installed in horizontal or vertical postion | Cells can be installed in vertical postion only |

| The gelled electrolyte has the advantage of no acid stratification and no failures due to the partial state of charge. | The flooded electrolyte has the advantage of no acid stratification and no failures due to the partial state of charge. |

| Self discharge is less than 1%per week | Self discharge is less than 3%per week |

| Design float Life is 20 years Plus | Operational Life is 20 years Plus |

| Complies with DIN 40 742 part 1, Tests according to IEC 60 896-21,22 and safety standards, ventilation DIN EN 50 272-2. | Complies with DIN 40 736 part 1, Tests according to IEC 60 896-11,IS 1651-2013 and safety standards, ventilation DIN EN 50 272-2. |

Microtex 2V OPzV cells are the most popular solar battery worldwide

Related Batteries

- OPzS Batteries

- NDP Batteries

- HDP Batteries

- 2V Tubular Gel Batteries

- 2V AGM VRLA Batteries

- 2V Flooded Batteries

Send us an inquiry, now.

Related Battery Blog Articles