What is tubular gel battery?

A tubular gel battery is a type of sealed lead-acid (SLA) cell that uses a gel electrolyte instead of liquid. The gel electrolyte is made up of sulfuric acid and silica fume, which forms a thick paste-like substance that holds the electrolyte in place and prevents it from leaking, even if the cell case is cracked or damaged. The electrodes inside the cell are made of tubular plates, which provide a larger surface area for chemical reactions to occur, resulting in a longer lifespan and better performance compared to traditional flat-plate batteries. Tubular gel batteries are commonly used in applications such as renewable energy systems, telecommunications equipment, and uninterruptible power supplies (UPS), where reliability and long service life are crucial.

There are distinct advantages of lead-acid technology compared to lithium-ion & other electrochemical systems. Affordability, reliability, recyclability and safety are key issues in choosing the right battery for a particular application and lead-acid batteries will score highly in these categories. There is, however, a drawback when using conventional flooded lead-acid batteries for deep cycle applications. This is the maintenance required in topping up the batteries due to water loss by gassing. In many applications, like in traction battery applications, there is a need to completely recharge a battery in a limited time frame.

This normally will require higher voltages which in turn leads to the breakdown and loss of water from the electrolyte through gassing. These flooded lead-acid batteries will require topping up with water, creating inconvenience and costs and in large installations which often requires expensive extraction equipment. There are also other disadvantages, particularly with transport, storage and disposal. The liquid acid in the lead-acid battery is classified as a hazardous material for transport. Whilst this is not considered a problem within the industry, which operates using safe and proven procedures, it is much better to immobilise the acid to prevent spillages.

Is a VRLA battery a gel battery?

A VRLA battery is not the same as a gel battery...

Gel and AGM batteries are both subtypes of VRLA (Valve Regulated Lead Acid) batteries, differentiated by the method of electrolyte immobilization.

A VRLA (Valve Regulated Lead Acid) battery is not the same as a gel battery, although they are both types of sealed lead-acid batteries.

VRLA batteries use an absorbed glass mat (AGM) to immobilize the electrolyte and typically have a starved electrolyte design, whereas gel batteries use a thickened electrolyte that has the consistency of gel. Both types of batteries are commonly used in applications where maintenance-free operation is desired, such as in backup power systems, UPSs, and solar energy systems.

However, they have different performance characteristics and may be better suited for different types of applications depending on factors such as temperature, discharge rate, and cycle life. It’s important to choose the right type of battery for your specific application to ensure optimal performance and longevity.

Difference between gel and tubular battery

What is the difference between a gel cell and a regular battery? This is a question we are often asked. In a tubular battery which is flooded, the acid is free-flowing inside the cells. There is a vent on the top through which water is added to compensate for the normal losses that take place due to gassing. The flooded cell or vented battery has to be used in a vertical position.

Tubular plate battery – how the acid is immobilized in Gel and AGM batteries

One fortunate consequence of acid immobilization is that it creates the ability to recombine the hydrogen and oxygen gases which are produced from the breakdown of water inside the cell when on charge. There are two principal methods for acid immobilization:

- Use of absorptive glass mat which holds the acid in place called AGM VRLA batteries &

- The other, adding a fine silica powder to make a gel as in a Tubular gel lead acid battery

Both methods, although very different, achieve the goal of immobilization in Gel and AGM batteries.

They also provide the added benefit of recombining the gases released on charge to reform water, thereby removing the need for the water-addition maintenance procedures mentioned earlier for flooded lead-acid batteries. Out of these two methods, the use of silica-gelled electrolytes is universally recognised as the best solution for deep discharge tubular gel lead acid cell designs. There are two main reasons for this: the first is that the use of gelled electrolyte allows a tubular positive lead plate to be used, which is recognised as providing the best deep cycle properties for lead-acid batteries. The second reason is that the stratification of acid associated with deep discharges and limited-voltage recharging without gassing is avoided, in tubular gel cell.

These are significant advantages if you have deep cycle requirements as in solar battery applications. The use of tubular lead plate batteries provides the most robust lead-acid tubular gel batteries design with the highest deep cycle capability of all lead-acid designs. The resistance to stratification, in tubular gel cell, is of great benefit in many applications which operate at a partial state of charge (PSoC) such as standby power, UPS and Solar Energy clean environment markets.

Tubular gel battery technology with ppt silica

The main advantages of the tubular gel batteries are the absence of the need to top up your battery. So why is the lack of topping up, such an advantage? You have to consider the problems of maintaining lead-acid batteries in remote locations with difficult access. In flooded batteries, if you forget to top up with water they can dry out and fail. The cost of maintaining these flooded batteries with regular monthly or quarterly visits can be very high. For a business, this can make an installation uneconomical.

Tubular Gel battery disadvantages?

Tubular gel batteries have minimal disadvantages in most deep-cycle applications. However, users should consider charging profile and temperature environment before selection.

While tubular gel batteries offer many advantages, no battery type is entirely without drawbacks. Examples include:

Slower charge acceptance compared to AGM

Less suited for high-rate discharge

Performance degradation in sub-zero temperatures

Tubular gel battery manufacturers in India for inverter applications

Tubular gel battery price

The other side of this expensive coin is the maintenance, particularly in commercial environments where equipment reliability is key to providing a reliable and regular service. If batteries powering essential equipment fail due to lack of maintenance, the ramifications for credibility and reputation can be considerable. For the private user, it can be equally frustrating. For example, having to access installed batteries and obtain distilled water sometimes is not so easy, not to mention keeping a log and records for possible warranty claims. And of course, there is the situation where we are simply extremely busy and accessing and maintaining batteries can be a really time draining exercise.

There are also those clean environments where charging batteries can produce damaging or even explosive fumes, particularly in confined spaces. This is relevant for batteries used in computer backup and medical equipment applications where batteries are kept in cabinets or inside complex and sensitive equipment. To remove fumes from charging batteries it is sometimes necessary to install expensive extraction equipment to remove explosive hydrogen gas and corrosive acid fumes from confined spaces in cabinets or equipment.

Tubular gel batteries are sealed and designed to prevent electrolyte leakage under normal operating conditions, making them ideal for sensitive environments

There are also clean environment applications as in hospitals and food storage. In these environments smells and corrosive gases could contaminate food or damage human health. Looking again to the consumer applications, the last thing they need is a battery in their home, garage or solar power bank, which is producing explosive gases or corrosive fumes on when on a charge.

Gel batteries are sealed batteries. They do not leak. There is no risk of acid leakages. They are maintenance-free. It classifies them as non-hazardous for transportation, by rail or air. Terminals do not have any corrosion.

However, no battery is 100% immune to leakage under catastrophic failure or prolonged overcharging (risk of casing rupture).

Tubular gel batteries have very long life

There is no risk of leakages in a tubular gel cell since the electrolyte is in gel form. Since they cannot leak the tubular gel battery can be used in any orientation. If the tubular gel battery falls or breaks, there will be no acid spills. There will be no environmental damage caused because of accidental spillage of acid like from a flooded battery. Tubular gel batteries are resistant to vibration & shocks.

All lead-acid VRLA batteries, including gel types, can emit gases if overcharged or used outside specifications. Tubular gel batteries release minimal gases under standard charging conditions due to internal gas recombination, significantly reducing the risk of explosive gas accumulation

They don’t release explosive gases like in large installations using flooded batteries.

Recovers from deep discharge quickly

While tubular gel batteries handle deep discharges better than flooded or AGM, recovery speed is influenced by charging voltage and time, and may be slower than AGM.

Tubular gel batteries can recover well from deep discharge scenarios due to their robust plate design, but full recovery depends on correct charging protocols.

Tubular gel batteries - important design feature

So just how do this combination of tubular lead plate and GEL electrolyte work? The sealed design with safety valves facilitates internal recombination of gases, minimizing the need for electrolyte maintenance.

To understand we have to look at several elements which contribute to the battery’s properties, these are:

An electrolyte which is immobilized as a GEL to ensure non-spillage and also to enable the transportation of hydrogen and oxygen released on charging to be recombined to form water. The benefit of immobilization extends further, it prevents the creation of strata of acid with different densities within the cells, called Acid Stratification.

In flooded batteries and sometimes AGM VRLA designs, denser gravity sulfuric acid produced at the lead plates during charge can drop to the bottom of the cell by gravity, leaving the weaker specific-gravity acid at the top. Batteries in this condition suffer early failure from sulfation, premature capacity loss (PCL) and grid corrosion. Tubular Gel batteries overcome this issue by the ‘gellification’ of the acid & do not suffer from acid stratification – a serious mode of failure in very tall cells needed to be kept vertical. Microtex have a Tubular gel battery-making plant imported from Germany and use high-grade imported fumed silica to give uncompromising life and performance to their tubular gel battery.

Absorbent glass mat or AGM batteries use a glass mat like a sponge to retain the sulfuric acid inside the cell. There is no free sulfuric acid & is generally called AGM batteries are classified as starved-electrolyte VRLA cells. The AGM type of cell uses flat lead plates for the positive & the negative electrodes, which unlike tubular positive plates are more prone to corrosion. AGM batteries have a lesser life compared to tubular gel types of batteries.

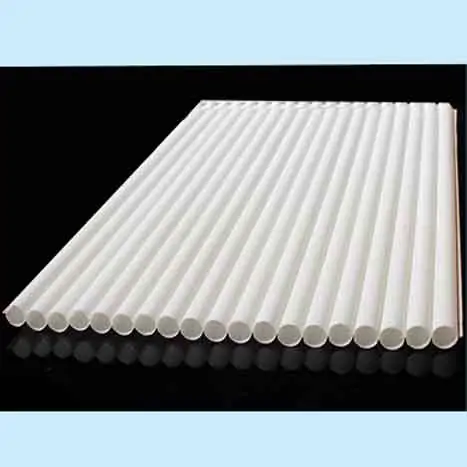

Tubular gel types of cell use the tubular design of the battery lead plate.

This is essentially a pressure cast lead alloy spine instead of a gravity-cast grid, which is covered by a fabric gauntlet and then filled with the positive active material (PAM). This can be either a dry lead oxide powder or a wet lead oxide slurry. A tubular gel cell design of plate has a couple of advantages: the first is that it has a higher surface area in contact with the sulfuric acid to give better material utilization (as much as 60%). (As seen in the pic above). The second reason is that in tubular gel batteries the cycle life can exceed 1800 cycles at 50% DoD under optimal charging.

Tubular vs gel battery

There are distinct advantages of lead-acid technology compared to lithium-ion batteries & other electrochemical systems. Affordability, reliability, recyclability and safety are key issues in choosing the right battery for a particular application and lead-acid batteries will score highly in these categories. There is, however, a drawback when using conventional flooded lead-acid batteries for deep cycle applications. This is the maintenance required in topping up the batteries due to water loss by gassing. In many applications, like in traction battery applications, there is a need to completely recharge a battery in a limited time frame.

This normally will require higher voltages which in turn leads to the breakdown and loss of water from the electrolyte through gassing. These flooded lead-acid batteries will require topping up with water, creating inconvenience and costs and in large installations which often requires expensive extraction equipment. There are also other disadvantages, particularly with transport, storage and disposal. The liquid acid in the lead-acid cell is classified as a hazardous material for transport. Whilst this is not considered a problem within the industry, which operates using safe and proven procedures, it is much better to immobilise the acid to prevent spillages.

Tubular gel lead acid battery - how the acid is immobilized in Gel and AGM batteries

One fortunate consequence of acid immobilisation is that it creates the ability to recombine the hydrogen and oxygen gases which are produced from the breakdown of water inside the battery when on charge. There are two principal methods for acid immobilization:

- Use of absorptive glass mat which holds the acid in place called AGM VRLA batteries &

- The other, adding a fine silica powder to make a gel as in a Tubular gel lead acid battery

Both methods, although very different, achieve the goal of immobilisation in gel and agm batteries.

They also provide the added benefit of recombining the gases released on charge to reform water, thereby removing the need for the water-addition maintenance procedures mentioned earlier for flooded lead-acid batteries. Out of these two methods, the use of silica-gelled electrolyte is universally recognised as the best solution for deep discharge tubular gel lead-acid designs. There are two main reasons for this: the first is that the use of gelled electrolyte allows a tubular positive lead plate to be used, which is recognised as providing the best deep cycle properties for lead-acid batteries. The second reason is that the stratification of acid associated with deep discharges and limited-voltage recharging without gassing is avoided, in tubular gel batteries.

These are significant advantages if you have deep cycle requirements as in solar applications. The use of tubular lead plate batteries provides the most robust lead-acid tubular gel batteries design with the highest deep cycle capability of all lead-acid designs. The resistance to stratification, in tubular gel battery is of great benefit in many applications which operate at partial state of charge (PSoC) such as standby power, UPS and Solar Energy clean environment markets.

Tubular gel batteries - Long life

There is no risk of leakages in a tubular gel cell since the electrolyte is in gel form. Since they cannot leak the tubular gel cell can be used in any orientation. If the tubular gel battery falls or breaks, there will be no acid spills. There will be no environmental damage caused because of accidental spillage of acid like from a flooded battery. Tubular gel batteries are resistant to vibration & shocks. They don’t release explosive gases like in large battery bank installations of flooded batteries.

Disadvantages of Tubular gel batteries – Besides a higher upfront cost, tubular gel batteries may have slightly slower charge acceptance and are heavier, but their lifecycle cost advantage and safety benefits often outweigh these factors.

They have a huge life span & come maintenance free!

Even with ROI benefits, disadvantages include:

Slower charge acceptance vs AGM

Less suited for high-rate discharges

Higher weight per Ah than Li-ion

Tubular gel batteries – Key designs

So just how do this combination of tubular lead plate and GEL electrolyte work? To understand we have to look at several elements which contribute to the battery’s properties, these are:

An electrolyte which is immobilized as a GEL to ensure non-spillage and also to enable the transportation of hydrogen and oxygen released on charging (which is held inside the battery under pressure) to be recombined to form water. The benefit of immobilization extends further, it prevents the creation of strata of acid with different densities within the cells, called Acid Stratification.

In flooded batteries and sometimes AGM VRLA designs, denser gravity sulfuric acid produced at the lead plates during charge can drop to the bottom of the cell by gravity, leaving the weaker specific-gravity acid at the top. Batteries in this condition suffer early failure from cell sulfation, premature capacity loss (PCL) and grid corrosion. Tubular Gel batteries overcome this issue by the ‘gellification’ of the acid & do not suffer from acid stratification – a serious mode of failure in very tall cells needed to be kept vertical. Microtex have a Tubular gel battery-making plant imported from Germany and use high-grade imported fumed silica to give uncompromising life and performance to their tubular gel battery.

Absorbent glass mat or AGM batteries use a glass mat like a sponge to retain the sulfuric acid inside the cell. There is no free sulfuric acid & is generally called a starved electrolyte condition cell. The AGM type of batteries uses flat lead plates for the positive & the negative electrodes, which unlike tubular positive plates are more prone to corrosion. AGM batteries have a lesser life compared to tubular gel types of battery.

Tubular gel types of battery uses the tubular design of the battery lead plate.

This is essentially a pressure cast lead alloy spine instead of a gravity casted grid, which is covered by a fabric gauntlet then filled with the positive active material (PAM). This can be either a dry lead oxide powder or a wet lead oxide slurry. A tubular gel cell design of plate has a couple of advantages: the first is that it has a higher surface area in contact with the sulfuric acid to give better material utilization (as much as 60%). (As seen in the pic above). The second reason is that tubular gel types of battery and 2v cells have the highest cycle life of the entire lead acid battery range.

The plate area contained in the linear distance a to c is dependent on the plate length L

Assuming that the plate length L will be the same for both plates, then the sulfuric acid contact area for one plate surface for both flat plate and tubular plate designs will be defined respectively by:

The length a to c (AC) times L and the length of the arcs ab and bc times L

Flat plate single side contact area = ca x L

Tubular plate single side contact area = (arc ab +arc bc) x L x (no of tubes-1)

Acid contact area of one surface of flat plate = L x ca

Acid contact area of one surface of tubular plate = (L x Π x ca)/2

Ratio of tubular plate area to flat plate area = (L x Π x ca)/2 (L x ca)

Approximate theoretical area increase of tubular/flat plate = Π/2=1.6

This disregards the plate edges & grid frame of the flat plate

Under standard deep cycle test conditions (80% depth of discharge), some 2v cells in tubular designs can achieve over 2,000 cycles before the capacity drops to 80% of its original value. The corrosion-resistant alloy used in the positive spine ensures the longest achievable life of any 2v VRLA tubular gel batteries on the market. Microtex makes their own lead alloys to ensure the highest quality and best specification for their 2v batteries. Using an optimized lead – calcium alloy with high tin content ensures that premature battery failures due to positive grid growth and spine corrosion are effectively prevented.

This is not the cheapest material and self-manufactured not the most convenient way of obtaining the components for lead-acid tubular gel batteries, but it does give the best form of control to meet the demanding quality standards for which Microtex tubular gel batteries are renowned.

Microtex’s specialized lead-calcium-tin alloys significantly reduce gas evolution during charging, enhancing recombination and minimizing water loss.

Because the volumes of gas produced are not excessive (as with conventional flooded battery designs) they can be recombined to form water within the operating pressure of the SMF battery. Because the Microtex alloys produce so little gas, premature failure due to water loss is prevented.

Hydrogen and oxygen gas are produced at the negative and positive electrodes respectively when water is broken down during charging. The simplified lead-acid battery reactions involving the negative oxygen and positive hydrogen ions produced when water is electrolyzed are:

• H₂O → ½ O₂ + 2H⁺ + 2e⁻ (at positive plate)

• 2H⁺ + 2e⁻ → H₂ (at negative plate)

From these simplified equations, we can see that the charged oxygen and hydrogen ions produced by the breakdown of water are in solution as ionic species.

It then attracts them to the oppositely charged electrodes where (because of the electrochemistry of the charging process) hydrogen is reduced by gaining an electron and oxygen is oxidized by losing an electron. Because the gases are then trapped, water is lost from the electrolyte. However, the tubular gel battery design efficiently contains these gases within the voids created in the immobilized electrolyte which now become small gas pockets. The immobilized gel matrix contains microvoids that temporarily hold gases, allowing for controlled recombination and preventing electrolyte drying.

Tubular Gel Battery demand high-quality materials of construction: In particular, the multitube gauntlet (PT Bags) used in the plate and the PVC separator are manufactured by Microtex to the most demanding specifications found in the lead-acid battery industry. This ensures a high burst pressure in the PT Bags gauntlet to resist cyclic volume changes of the active material. This volume change can lead to paste shedding and loss of capacity if lower grade materials with a lower burst strength PT Bags are used.

Likewise, Microtex’s Time Tested PVC separator has optimum porosity, low shrinkage and high stability in sulphuric acid. This ensures that the tubular gel battery will meet its design criteria with minimum internal resistance and guaranteed life, even under very arduous conditions.

No-compromise on the material specifications for bought-in components such as the pressure relief valve used to control the cell internal pressure. Unless the pressure relief valves have precisely the same opening pressures there could be water loss from some cells due to gases escaping. This causes imbalances between the individual cells of a tubular gel battery which leads to early failure. Use of the highest-quality components ensures that there is minimal internal resistance cell to cell variation during a tubular gel battery’s operation.

Similarly, the connectors and containers use the best materials for the job and are supplied by certified manufacturers to Microtex’ demanding specifications. The Microtex designs, constructional materials and specifications for bought-in components are the result of decades of experience and closely working with and supporting their suppliers and customers. It is this dedicated and no-compromise approach to customer satisfaction that helps to set Microtex apart from their competitors.

Good balance of active materials within the tubular gel battery.

Performance and life depend on the interaction of the three electrochemical materials — PAM, NAM, and acid — along with plate design, separator quality, and assembly precision.

In a fully charged lead acid battery, the PAM is lead dioxide and the NAM is spongy pure lead. These react together with the sulphuric acid electrolyte to form lead sulphate and water in the following battery reaction:

• PbO2 + Pb + 2H2SO4 = 2PbSO4 + 2H2O

• (PAM) (NAM) (ACID) (Discharged plates) (Water)

This is known as the double sulphate theory and it predicts the minimum amount of active materials required to provide the rated capacity of the battery.

However, this is the real, not the theoretical world. In practice, the physical characteristics, quality of the materials and the quality of the manufacturing processes will also influence how much material is required and how long the battery will last in service. The PAM has a lower efficiency than the NAM and up to 20%, more may be needed to provide the same capacity as the negative material. Added to this is the utilization of the material, the higher the utilization the lower the life expectancy. To complicate matters the optimized balance changes when considering recombination tubular gel battery.

Microtex, in association with international German and British experts, has optimized the materials and the manufacturing process to produce the best possible balance between the plate materials and sulfuric acid content in its tubular gel battery. It is fair to say that the performance and life expectancy of tubular gel batteries are probably the envy of the rest of the lead acid battery industry.

Other important aspects of a tubular gel battery’s usefulness are its range and sizes. There are numerous applications mostly with different capacities, voltages and performance requirements. In addition to this, there are the containers or spaces where the batteries have to be fitted and, in these instances, the skill of the person installing them is also an important consideration. In this respect Microtex has covered all the bases, the Microtex tubular gel battery extensive range of 12v monobloc and 2V tubular gel battery cells comes in a variety of sizes and capacities to meet stringent requirements of even Nuclear power stations.

The tubular gel battery banks are fully insulated and designed to carry the high loads necessary for occasional or frequent high-rate discharges. The complete range of 2v OPzV tubular gel battery provides for applications like telecom, solar, standby, switchgear and controls, power generating stations and substations, nuclear and thermal power stations, electricity transmission substations with reliable and durable backup power and energy storage.

Made to order or standard size batteries in insulated steel containers are no problem for the Microtex technical and manufacturing teams. High-level technical assistance is available at no extra cost to help customers in designing the optimum and most cost-effective installation for their requirements. This includes designing and fitting zone 4 seismic racks and enclosures on customers’ premises.

References: