Forklift Batteries

Discover the Best Forklift Battery!

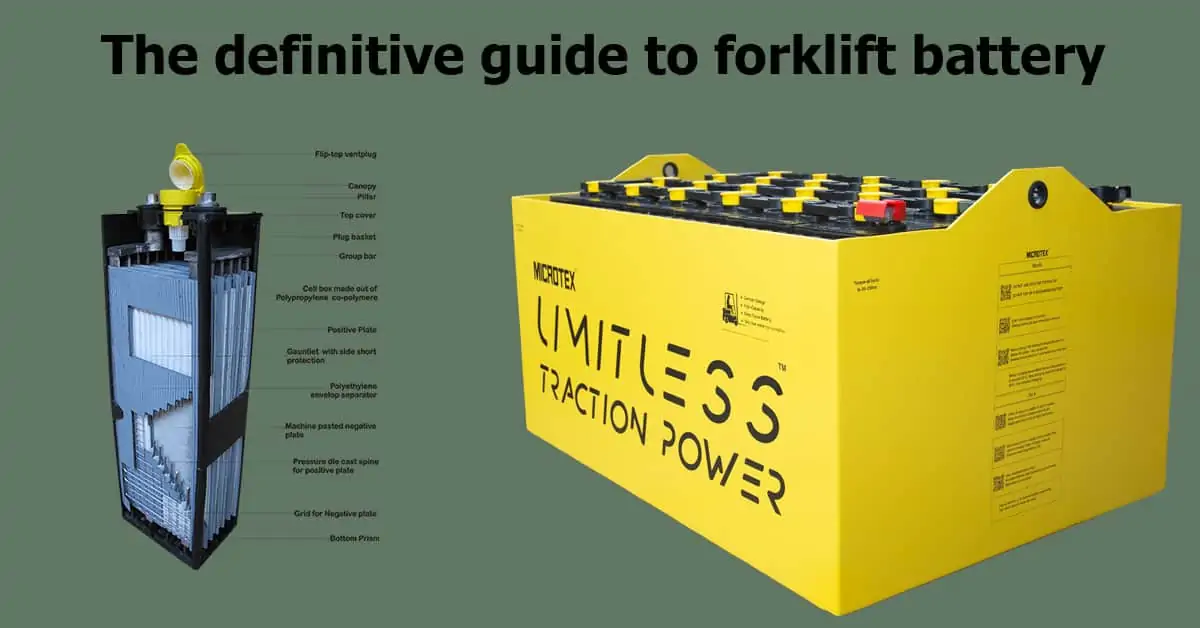

Microtex, the leading manufacturer and supplier of high-performance forklift batteries in India. With decades of expertise and a commitment to quality and innovation, we offer top-of-the-line forklift batteries designed to meet the rigorous demands of material handling equipment. Our batteries are engineered for durability, efficiency, and long service life, ensuring that your forklifts operate smoothly and reliably. Whether you need batteries for electric forklifts, stackers, or pallet trucks, Microtex has the perfect solution for your needs.

Microtex:

Your Premier Source for Forklift Batteries

Why Microtex lead-acid Batteries for forklift?

Understanding Forklift Batteries

What are Forklift Batteries?

Forklift batteries, also known as traction batteries, are specifically designed to power electric forklifts and other material handling equipment. These batteries are built to provide sustained power over extended periods, making them ideal for intensive, high-duty cycle operations in warehouses, distribution centers, and manufacturing facilities. Forklift batteries are typically deep-cycle batteries, meaning they are capable of being discharged and recharged many times over their lifespan.

Key Features of Microtex Forklift Batteries

Microtex forklift batteries are designed with advanced technology and high-quality materials to ensure superior performance and reliability. Key features include:

- High Energy Density: Our batteries are engineered to provide maximum energy output, ensuring that your forklifts operate efficiently throughout the workday.

- Long Cycle Life: Designed for durability, Microtex forklift batteries offer an extended cycle life, reducing the frequency of replacements and lowering total cost of ownership.

- Deep Discharge Capability: Our batteries can handle deep discharge cycles without compromising performance, making them ideal for demanding material handling operations.

- Fast Charging: Microtex forklift batteries with nano carbons & graphene support fast charging, minimizing downtime and maximizing productivity.

- Robust Construction: Built to withstand harsh operating conditions, our batteries feature rugged construction and high-quality components.

Applications of Forklift Batteries

Forklift batteries are essential for a wide range of applications across various industries. Key applications include:

Warehousing and Distribution

In warehousing and distribution centers, forklifts are used for a variety of material handling tasks, including loading and unloading trucks, transporting goods, and organizing inventory. Reliable forklift batteries are crucial for ensuring efficient and uninterrupted operations.

Manufacturing

Manufacturing facilities rely on forklifts for moving raw materials, transporting finished products, and managing inventory within the plant. High-performance forklift batteries enable smooth and efficient material handling, contributing to overall productivity and efficiency.

Retail and Wholesale

Retail and wholesale businesses use forklifts to manage inventory, restock shelves, and handle large quantities of goods. Forklift batteries that offer long runtime and quick charging are essential for maintaining the fast-paced operations of these businesses.

Cold Storage

Cold storage facilities require forklifts that can operate efficiently in low-temperature environments. Microtex forklift batteries are designed to perform reliably even in cold storage conditions, ensuring consistent power and performance.

Agriculture

In agricultural settings, forklifts are used for various tasks, such as transporting produce, loading equipment, and handling materials. Durable and reliable forklift batteries are essential for ensuring the smooth operation of agricultural machinery.

Why Choose Microtex Forklift Batteries?

Choosing Microtex forklift batteries offers several advantages:

Proven Performance: Microtex has a long history of manufacturing high-quality forklift batteries that deliver consistent and reliable performance. Our batteries are trusted by leading businesses across various industries.

Innovative Technology: We leverage advanced technology and innovative manufacturing processes to produce forklift batteries that offer superior performance, efficiency, and longevity.

Stringent Quality Control: Quality is at the heart of everything we do. Our forklift batteries undergo rigorous testing and quality control measures to ensure they meet the highest standards of performance, safety, and durability.

Expert Support: Our team of experts is always available to provide technical support and guidance. Whether you need assistance with product selection, installation, or maintenance, we are here to help.

Sustainability: We are committed to sustainability and environmentally responsible manufacturing practices. Our forklift batteries are designed to be eco-friendly and recyclable, contributing to a greener future.

German Designs - Made for Indian conditions

Microtex batteries are designed by Dr Wieland Rusch a leading battery scientist & inventor of the copper stretch metal submarine battery design.

Comparable to any leading international brands of batteries – our designs match with the best in the world.

Established in 1969, Microtex is known for its legendary quality

Microtex batteries are known the world over for its dependable & reliable battery performance

Unlike competitors, Microtex makes the complete battery & all its components in house

Microtex produces in house, the specially designed lead alloys, lead oxides, grid castings, pasted plates, injection-moulded containers, multi-tubular gauntlets (PT Bags), PVC separators and produces the complete battery using state of the art industry standard battery making machinery.

Complete Range of Motive Power cells in DIN & BS Types of batteries

Microtex offers the complete international range of fork lift batteries meeting recognized European German & British standards

- 2v PzS traction cells from 100Ah to 1550Ah

- 2v PzB traction cells from 42Ah to 1404Ah

All our traction batteries are designed by the reputed German Battery Scientist Dr Wieland Rusch. Manufacturing of electrodes with effective utilization of the positive active materials provides for multi-shift operations with higher discharge efficiency providing better performance in opportunity charging, with minimum watering making it feel almost like a maintenance-free battery. Gives the best ROI on initial investment providing best total cost of ownership.

Microtex have been exporting batteries from 1977!

Very few battery companies can claim to have been exporting traction batteries for so long!

Our Traction Batteries have seen life of 8 to 10 years

The TRUTH about how To Choose a Dependable Forklift Battery...

even if You Have Been Told All Traction Batteries Are Plus Or Minus The Same Thing!

This is to certify that Traction Battery type 48v 470Ah supply by you in the year 2008 is working in Good Condition and Performance is satisfactory. We are getting good service support from Microtex.

2-7-2019: Woory Automotive India Pvt Ltd - Tamil Nadu Tweet

This is to certify that Traction Battery type 36v 756Ah supply by you in the years 2012 and 2018 is working in Good condition and performance is satisfactory. Both batteries are fixed in Crown Reach Truck. We are getting good service support from Microtex. Snowfield Cold Storage - Tamil Nadu

25-1-2020: Snowfield Cold Storage - Tamil Nadu Tweet

At Microtex we believe our customers must get the best traction battery performance & life consistently. To this end, we leave no stone un-turned to ensure that you get a superior battery built with great care & passion.

How can forklift batteries help your business?

- Forklift batteries can help your business in a number of ways. First and foremost, they provide reliable power for your forklifts, allowing them to operate efficiently and effectively. Forklift batteries are designed to provide consistent power over a long period of time, so you don’t have to worry about running out of juice midway through a job.

- In addition to ensuring reliable operation, forklift batteries can also help your business save money. By switching to electric forklifts powered by batteries, you can reduce your fuel costs and lower your carbon footprint. Electric forklifts are generally more efficient than gas or diesel-powered models, meaning you can get more work done with the same amount of energy.

- Finally, forklift batteries can improve safety in your workplace. Because they produce zero emissions, electric forklifts are better suited for indoor use than gas or diesel-powered models. They also tend to be quieter and easier to operate, reducing the risk of accidents or injuries on the job.

- Overall, investing in high-quality forklift batteries can be a smart move for any business that relies on material handling equipment to get the job done.

How Long do Forklift Batteries Last?

The lifespan of a forklift battery depends on several factors, including the type and size of the battery, how often it is used, and how well it is maintained. Typically, forklift batteries can last anywhere from 1,500 to 2,000 charge cycles, which translates to about 5 years of use. However, with proper maintenance and care, some batteries may last even longer. It is important to follow the manufacturer’s recommended maintenance schedule for your specific battery and to monitor its performance regularly to ensure that it is functioning properly. Signs that your forklift battery may need replacement include reduced run time, slow charging times, or issues with overheating or other damage. Forklift Battery replacement: When it comes time to replace your forklift battery, be sure to choose a high-quality replacement that is compatible with your machine and meets your performance needs.

What are forklift batteries?

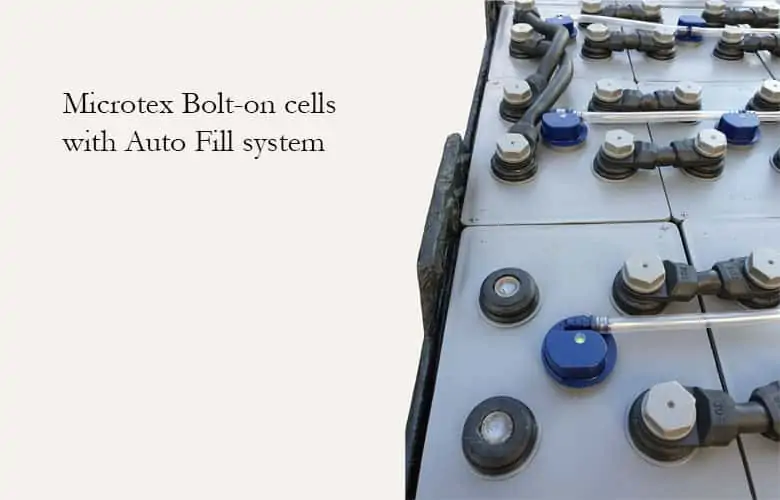

Microtex Limitless Traction batteries for the battery-operated forklift industry is India’s most widely used lead-acid traction battery. They are used as power sources for electric forklifts, stackers, and platform trucks. Microtex Motive Power 2v cells are available in the complete range of all available internationally approved forklift batteries sizes both in British & DIN specifications. Ranging from 24 to 96 volt. Microtex electric forklift battery are highly optimized. This type of battery design ensures optimal utilization of positive & negative electrode active mass to provide maximum power output. We offer forklift battery with welded & bolt-on terminals.

Designed by Dr Wieland Rusch of Germany – Manufactured with precision and pride in India, we make complete traction batteries and all its components in house ensuring a high level of quality without having to depend on outside vendors.

While there are different types of forklift batteries, Microtex 2v traction battery is made from completely formed plates; & not green plates, formed after assembly. This is to eliminate any chance of unformed active material in the electrodes.

What sets our forklift battery apart from the rest?

- Microtex Limitless Traction batteries are available in the complete internationally approved dimensions for BS & DIN designs with either welded or bolt-on terminals from 40Ah to 1440Ah

- How long does a forklift battery last? Operational Life: >1500 cycles operation @25°C

- Reduced Maintenance requirements: due to the very low antimony design with selenium as grain refiners, the need to top-up frequently is vastly reduced

- IEC 60 254-1 cycles: >1500

- Self-discharge: Approx 2% per month at 25°C

- Recovery after deep discharge: Very good

- Operational temperature: -20°C to 45°C, recommended 10°C to 35°C, short time 45°C to 55°C

- Reliability: Peace of mind that the Forklift battery power supply will remain constant; with longer power available through out the shift.

- German Design: With balanced active materials delivers forklift battery capacity that meets international specifications

- Durability: Robust heavy-duty construction, thicker spines, coupled with deep-discharge performance

- Price: A realistic, and competitive forklift battery price

- Delivery: fastest 21 days assured on time delivery, every time; Guaranteed

- After-sales: A fully committed, PAN India customer care service is available a phone call away to solve any forklift battery maintenance issue quickly and efficiently

Made in India with German Technology

- Forklift Battery Terminal Connectors designed for the rated capacity without causing terminal melting or connector melting (common failure mode during service)

- High-quality hardened lead alloys used in terminals & connectors, also with brass inserts

- Trouble-free battery performance throughout its 5 year expected life (Microtex Limitless Traction batteries have seen 11 years performance also)

- Designer Low antimony-tin-selenium lead alloys ensure the need for frequent water topping up is substantially reduced

- A dedicated support team for customer service to help you with the forklift battery replacement

- Our service engineers will come over & take the dimensions & our design team will provide you with an engineering drawing of the forklift battery for your approval. This is our standard practice.

- Microtex Traction batteries have been exported from 1977! Not many companies can claim to have this!

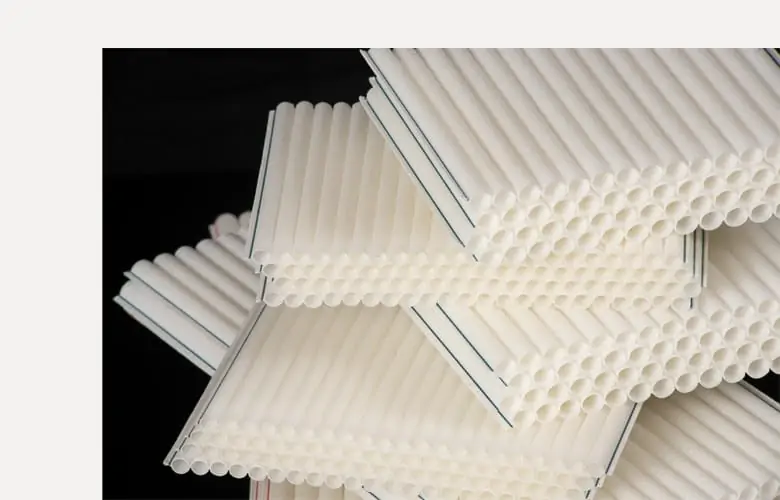

- Microtex Limitless Traction batteries are supplied only with woven tubular bags we do not use non-wovens

- Microtex high-frequency forklift battery chargers are readily available

Do you need a Forklift battery replacement?

Send us an inquiry, now.

Forklift battery general information

Microtex Limitless Traction batteries are available with Traction 2v cells with lead-acid technology for forklifts

48v Traction Battery

12v

24v

36v

80v

96v

Custom-built options available

All forklift batteries are available in International standard designs BS (British Standards) capacities from 42Ah to 1404Ah

& in DIN designs (German Standards) capacities from 100Ah to 1505Ah

Custom-built Microtex Limitless Traction batteries are delivered in 21 days. Assured delivery.

- Each forklift battery is placed on a pallet secured well & is packed suitably for safe transport. Each battery is accompanied with a Tree Sapling & a user kit which includes necessary tools for the battery maintenance like, multi meter, hydrometer, insulated spanner, etc.

- All batteries come with our standard 1 year warranty

- Within India you can avail an extended 1 year warranty if you plant the tree sapling & please see the attached tag on the plant for terms.

Forklift Battery Technical specifications

Microtex Limitless Traction batteries meet stringent International Standards and meets electrical performance to comply with:

- IS 5154 2013 (Part 1 & 2)

- IEC 60254-1:2005

- IEC 60254-2:2008

Our labs are equipped with state-of-the-art high-quality life-cycle testers from world-class suppliers Bitrode and Digatron to ensure our batteries stand meet the required electrical parameters to the test of time.

Disclaimer: Please note all the forklift manufacturers names mentioned are purely for reference. Microtex is not associated with the companies. All names belong to respective forklift manufacturers.

| Original Equipment Manufacturer | Material Handling Equipment Model | Microtex Battery Type | Voltage | Ampere- hour | Max. Overall Dimensions (mm) Tolerance = + 5 mm | ||

| Length | Width | Height | |||||

| Ace | AEPT-22 | 12x3MIPzB160 | 24 | 160 | 750 | 180 | 460 |

| Ace | AES-15 | 12x3MIPzB206 | 24 | 206 | 750 | 175 | 530 |

| Ace | AES-15-SS/W | 12x3MIPzB240 | 24 | 240 | 745 | 175 | 530 |

| Ace | AES-18-C | 12x33MIPzS330 | 24 | 330 | 795 | 210 | 630 |

| Ace | AEWS-12 | 12x3MIPzB180 | 24 | 180 | 750 | 180 | 490 |

| Ace | APFT | 2x67MIPzB230 | 2X12 | 230 | 520 | 270 | 330 |

| Baka | EGU Pallet | 12 X 3MIPzB225 | 24 | 225 | 723 | 220 | 560 |

| Baka | EGV Stacker | 12 x 3MIPzS270 | 24 | 270 | 792 | 220 | 570 |

| Dilip | Electric Stacker OR | 12x3MIPzB206 | 24 | 206 | 750 | 175 | 530 |

| Dilip | Electric Stacker Spl | 12x3MIPzS240 | 24 | 240 | 650 | 295 | 450 |

| Dilip | Electric Stacker DPS 15/22 | 2x6x2MIPzS150 | 2×12 | 150 | 290 | 206 | 445 |

| Dilip | Electric Pallet | 12x3MIPzB166 | 24 | 166 | 664 | 220 | 523 |

| Dilip | Electric Stacker Spl | 12x3MIPzS330 | 24 | 330 | 795 | 210 | 630 |

| Dilip | Electric Stacker Spl | 2x6x3MIPzS330 | 2×12 | 330 | 405 | 210 | 630 |

| FTS/FTE | Power pallet truck (1.0, 1.5, 2.0MT) | 12 X 3MIPzB195 | 24 | 195 | 723 | 221 | 533 |

| FTS/FTE | Power pallet truck (3.0 & 4.0MT) | 12 X 3MIPzB225 | 24 | 225 | 723 | 221 | 533 |

| FTS/FTE | Stacking truck (1.0MT & 1.25MT) | 12 x 6MIPzB252 | 24 | 252 | 699 | 335 | 440 |

| FTS/FTE | Pedestrain Electrick Fork Truck | 12 x 6MIPzB252 | 24 | 252 | 518 | 468 | 392 |

| FTS/FTE | Rider Electrick Platform truck – 2MT | 18 x 5MIPzB210 | 36 | 210 | 1022 | 914 | 637 |

| FTS/FTE | Rider Electrick Platform truck – 3MT | 18 x 8MIPzB336 | 36 | 336 | 1000 | 474 | 400 |

| FTS/FTE | Rider Electrick Forklift truck – 1MT | 24 x 8MIPzB336 | 48 | 336 | 902 | 718 | 518 |

| FTS/FTE | Rider Electrick Platform truck – 4MT | 24 x 8MIPzB336 | 48 | 336 | 902 | 718 | 518 |

| FTS/FTE | Rider Electrick Forklift truck – 1.5MT | 24 x 8MIPzB440 | 48 | 440 | 902 | 718 | 518 |

| FTS/FTE | Rider Electrick Forklift truck – 2MT | 24 x 8MIPzB520 | 48 | 520 | 902 | 718 | 518 |

| FTS/FTE | Rider Electrick Forklift truck – 2.5MT | 36 x 8MIPzB336 | 72 | 336 | 1022 | 914 | 637 |

| FTS/FTE | Rider Electrick Forklift truck – 3MTr | 36 x 8MIPzB440 | 72 | 440 | 1022 | 914 | 637 |

| Godrej & Boyce | CROWN WE 2000 | 12 X 3MIPzS375 | 24 | 375 | 820 | 215 | 625 |

| Godrej & Boyce | G050E/G075E | 18 x 8MIPzB336 | 36 | 336 | 830 | 630 | 400 |

| Godrej & Boyce | G050E/G075E | 18 x 8MIPzB336 | 36 | 336 | 500 | 470 | 400 |

| Godrej & Boyce | G075E/G100E(S) | 18 x 8MIPzB440 | 36 | 440 | 830 | 630 | 495 |

| Godrej & Boyce | G075E/G100E(S) | 18 x 8MIPzB440 | 36 | 440 | 500 | 470 | 495 |

| Godrej & Boyce | G100E(S) | 18 x 8MIPzB520 | 36 | 520 | 830 | 630 | 533 |

| Godrej & Boyce | G100E(S) | 18 x 8MIPzB520 | 36 | 520 | 500 | 470 | 533 |

| Godrej & Boyce | G100E(L) | 18 x 8MIPzB520 | 36 | 520 | 825 | 611 | 537 |

| Godrej & Boyce | G150E | 18 x 8MIPzB520 | 36 | 520 | 990 | 475 | 540 |

| Godrej & Boyce | G150E1.5T | 18 x 9MIPzB585 | 36 | 585 | 1000 | 499 | 520 |

| Godrej & Boyce | G200E | 18 x 12MIPzB660 | 36 | 660 | 990 | 675 | 533 |

| Godrej & Boyce | G200E (OLD) | 18 x 11MIPzB715 | 36 | 715 | 990 | 700 | 550 |

| Godrej & Boyce | Ec40 | 18 x 12MIPzB780 | 36 | 780 | 990 | 641 | 533 |

| Godrej & Boyce | Ec40 | 18 x 12MIPzB780 | 36 | 780 | 860 | 827 | 534 |

| Godrej & Boyce | CROWN SC 1.25 | 24 x 3MIPzS375 | 48 | 375 | 830 | 412 | 625 |

| Godrej & Boyce | CROWN ESR 1.4 | 24 x 3MIPzS465 | 48 | 465 | 1220 | 280 | 790 |

| Godrej & Boyce | CROWN SC 1.6 | 24 x 4MIPzS500 | 48 | 500 | 820 | 518 | 625 |

| Godrej & Boyce | GX150E/GX200E | 24 x 8MIPzS520 | 48 | 520 | 1020 | 700 | 570 |

| Godrej & Boyce | G200E2.0T/GX250E/GX300E | 24 x 10MIPzB650 | 48 | 650 | 1000 | 735 | 560 |

| Godrej & Boyce | EC70(3T) | 36 x 8MIPzB520 | 72 | 520 | 1000 | 892 | 533 |

| Jaldoot | Pallet truck | 12 X 3MIPzB195 | 24 | 195 | 723 | 221 | 533 |

| Jaldoot | Pallet truck | 12 X 3MIPzB225 | 24 | 225 | 723 | 221 | 600 |

| Jaldoot | 3 Wheeler platform | 15 x 4MIPzB220 | 30 | 220 | 856 | 355 | 504 |

| Jaldoot | 3 Wheeler platform | 15 x 6MIPzB330 | 30 | 330 | 856 | 355 | 504 |

| Jaldoot | 4 Wheeler platform | 18 x 8MIPzB336 | 36 | 336 | 1000 | 467 | 395 |

| Josts | PIGMY | 2 x 6 x 3MIPzB165 | 24 | 165 | 402 | 178 | 475 |

| Josts | Pallet truck | 12 X 3MIPzB225 | 24 | 225 | 664 | 221 | 600 |

| Josts | Stacker | 12 X 3MIPzS375 | 24 | 375 | 820 | 215 | 625 |

| Josts | 2T, 3 Wheeler platform | 15 x 4MIPzB220 | 30 | 220 | 856 | 355 | 504 |

| Josts | 2T, 3 Wheeler platform | 15 x 6MIPzB330 | 30 | 330 | 856 | 355 | 504 |

| Josts | 2T, 4 Wheeler platform | 18 x 8MIPzB336 | 36 | 336 | 1000 | 474 | 400 |

| KION | 24x4MIPzS 620 | 48 | 620 | 1220 | 355 | 780 | |

| KION | 12x3MIPzS 315 | 24 | 315 | 624 | 284 | 627 | |

| KION | 6MIPzB 450 | 72 | 450 | 978 | 695 | 600 | |

| KION | 12x3MIPzB 166 | 24 | 166 | 660 | 220 | 530 | |

| KION | 24x5MIPzS 575 | 48 | 575 | 827 | 627 | 627 | |

| KION | 24x10MIPzB 550 | 48 | 550 | 1000 | 720 | 530 | |

| KION | 12x3MIPzB 258 | 24 | 258 | 750 | 175 | 665 | |

| KION | 12x4MIPzB 280 | 24 | 280 | 642 | 242 | 565 | |

| KION | 8MIPzB 516 | 72 | 516 | 1022 | 914 | 637 | |

| KION | 12x3MIPzS 345 | 24 | 345 | 800 | 210 | 630 | |

| KION | 24x8MIPzB 440 | 48 | 440 | 902 | 718 | 518 | |

| Maini | SP16 | 2 x 6 x 2MIPzS160 | 24 | 160 | 298 | 212 | 466 |

| Maini | Stacker | 2 x 6 x 3MIPzB195 | 24 | 195 | 428 | 175 | 520 |

| Maini | SL22SPL(Old) | 12 X 3MIPzB195 | 24 | 195 | 800 | 177 | 525 |

| Maini | SE5/EPT | 2 x 6 x 7MIPzB224 | 24 | 224 | 510 | 275 | 330 |

| Maini | ST-10 | 12 X 3MIPzS240 | 24 | 240 | 792 | 210 | 510 |

| Maini | SE50T(Old) | 12 x 4MIPzS240 | 24 | 240 | 620 | 365 | 400 |

| Maini | ST-15/SC-18 | 12 X 3MIPzS375 | 24 | 375 | 795 | 210 | 615 |

| Maini | ST-10 | 12 X 3MIPzS375 | 24 | 375 | 795 | 210 | 615 |

| Maini | Tow Tractors (Old) | 12 x 6MIPzB450 | 24 | 450 | 680 | 330 | 590 |

| Maini | TGT-20/50 | 24 x 3MIPzS240 | 48 | 240 | 794 | 415 | 480 |

| Macneil | Commuter | 12 X 3MIPzB195 | 24 | 195 | 723 | 221 | 533 |

| Macneil | HDC 1.0 | 12 X 3MIPzB225 | 24 | 225 | 723 | 220 | 600 |

| Macneil | HDS 1.25 | 12 X 3MIPzB225 | 24 | 225 | 723 | 220 | 600 |

| Macneil | HI-STACK (HS-1010) | 12 x 6MIPzB252 | 24 | 252 | 518 | 468 | 392 |

| Macneil | HI-LIFT 1005/HI-STACK 1110 | 12 x 6MIPzB252 | 24 | 252 | 699 | 335 | 440 |

| Macneil | HI-LIFT 1008 | 12 x 6MIPzB252 | 24 | 252 | 699 | 335 | 440 |

| Macneil | HI-LIFT 1008 (Tilting) | 2 x 6 x 6MIPzB252 | 24 | 252 | 363 | 338 | 400 |

| Macneil | HDC 1.25 / HDC 1.5 | 12 x 4MIPzB300 | 24 | 300 | 660 | 260 | 592 |

| Macneil | HDS 1.5 | 12 x 4MIPzB300 | 24 | 300 | 660 | 260 | 592 |

| Macneil | HDC 1.75 | 12 x 6MIPzB330 | 24 | 330 | 696 | 340 | 480 |

| Macneil | Towmaster (TM-2040) | 24 x 6MIPzB192 | 48 | 192 | 972 | 524 | 463 |

| Macneil | Hi Reach | 12 x 6MIPzB750 | 24 | 750 | 497 | 464 | 838 |

| Macneil | Hi Reach | 12 x 6MIPzB750 | 24 | 750 | 271 | 287 | 838 |

| Macneil | HR 1015 | 12 x 6MIPzS775 | 24 | 775 | 497 | 464 | 838 |

| Macneil | HR 1015 | 12 x 6MIPzS775 | 24 | 775 | 271 | 287 | 838 |

| Macneil | R 1020 | 24 x 10MIPzB650 | 48 | 650 | 921 | 884 | 572 |

| Macneil | R 5010 | 2 x 12 x 5MIPzB275 | 48 | 275 | 920 | 528 | 448 |

| Macneil | Ranger 1010 | 24 x 8MIPzB336 | 48 | 336 | 902 | 718 | 518 |

| Macneil | Transloader (TL-2040) | 24 x 8MIPzB336 | 48 | 336 | 997 | 733 | 435 |

| Macneil | Transloader (TL-2140) | 24 x 8MIPzB336 | 48 | 336 | 965 | 345 | 450 |

| Macneil | Ranger 1015 | 24 x 8MIPzB440 | 48 | 440 | 902 | 718 | 518 |

| Macneil | Ranger 1020 | 24 x 8MIPzB520 | 48 | 520 | 902 | 718 | 518 |

| Macneil | Ranger 1020 | 24 x 8MIPzB600 | 48 | 600 | 902 | 718 | 625 |

| Macneil | Ranger 1025 | 36 x 8MIPzB336 | 72 | 336 | 1022 | 914 | 637 |

| Macneil | Ranger 1025 | 36 x 8MIPzB440 | 72 | 440 | 1022 | 914 | 637 |

| Macneil | Ranger 1030 (With counter weight) | 36 x 8MIPzB440 | 72 | 440 | 1022 | 914 | 637 |

| Macneil | Ranger 1030 | 36 x 8MIPzB520 | 72 | 520 | 1022 | 914 | 637 |

| Macrotech | Battery operated pallet | 12 X 3MIPzB195 | 24 | 195 | 723 | 221 | 533 |

| Macrotech | Battery operated pallet truck | 12 X 3MIPzB225 | 24 | 225 | 723 | 220 | 600 |

| Macrotech | Stradle Typestacker | 12 x 4MIPzB252 | 24 | 252 | 699 | 335 | 600 |

| Macrotech | Battery operated stacker | 12 x 6MIPzB252 | 24 | 252 | 518 | 468 | 392 |

| Macrotech | Straddle type Stacking truck | 12 x 6MIPzB252 | 24 | 252 | 699 | 335 | 600 |

| Macrotech | Forklift truck – 1MT (MT1010) | 24 x 8MIPzB336 | 48 | 336 | 902 | 718 | 518 |

| Macrotech | Forklift truck – 1.5MT (MT1015) | 24 x 8MIPzB440 | 48 | 440 | 902 | 718 | 518 |

| Macrotech | Forklift truck – 2MT (Mt1020) | 24 x 8MIPzB520 | 48 | 520 | 902 | 718 | 518 |

| Mahindra & Stiller | 18x5MIPzS 300 | 36 | 300 | 915 | 423 | 460 | |

| Mahindra & Stiller | 24x5MIPzB 300 | 48 | 300 | 965 | 385 | 565 | |

| Mahindra & Stiller | 24x8MIPzB 320 | 48 | 320 | 1000 | 600 | 400 | |

| Mahindra & Stiller | 12x3MIPzB 244 | 24 | 224 | 750 | 175 | 570 | |

| Mahindra & Stiller | 12x8MIPzB 480 | 24 | 480 | 870 | 350 | 520 | |

| Mahindra & Stiller | 15x6MIPzB 300 | 30 | 300 | 820 | 350 | 510 | |

| Mahindra & Stiller | 36x8MIPzB 440 | 72 | 440 | 995 | 914 | 480 | |

| Nilkamal | DC Stacker | 12x3MIPzB210 | 24 | 210 | 640 | 192 | 575 |

| Nilkamal | AC Stacker 1232 | 12x3MIPzS210 | 24 | 210 | 790 | 212 | 460 |

| Nilkamal | AC Stacker | 12x2MIPzS210 | 24 | 210 | 624 | 212 | 627 |

| Nilkamal | DC Stacker | 12x4MIPzB280 | 24 | 280 | 642 | 242 | 565 |

| Nilkamal | AC Stacker | 12x3MIPzS280 | 24 | 280 | 624 | 284 | 627 |

| Nilkamal | Electric Forklift | 12x5MIPzB310 | 24 | 310 | 645 | 290 | 480 |

| Nilkamal | DC Stacker | 12x5MIPzB350 | 24 | 350 | 642 | 290 | 575 |

| Nilkamal | AC Stacker | 12x3MIPzS350 | 24 | 350 | 624 | 284 | 627 |

| Nilkamal | Electric Forklift | 12x5MIPzS400 | 24 | 400 | 807 | 317 | 530 |

| Nilkamal | 1.5 Elec FL | 24x5MIPzB450 | 48 | 450 | 992 | 396 | 768 |

| Nilkamal | Reach Truck | 24x5MIPzB500 | 48 | 500 | 990 | 390 | 770 |

| Nilkamal | Electric Forklift | 24x5MIPzS630 | 48 | 630 | 1020 | 565 | 780 |

| Nilkamal | Electric Forklift | 40x4MIPzS500 | 80 | 500 | 1020 | 704 | 780 |

| Nilkamal | Electric Forklift | 40x7MIPzS700 | 80 | 700 | 1127 | 795 | 820 |

| OVIS Equipments | Trolley | 2x9x6MIPzS300 | 2×18 | 300 | 610 | 370 | 340 |

| OVIS Equipments | Trolley | 55x8MIPzB380 | 110 | 380 | 1130 | 295 | 440 |

| OVIS Equipments | Trolley | 55x8MIPzB300 | 110 | 300 | 1170 | 310 | 390 |

| OVIS Equipments | Trolley | 55x5MIPzB300 | 110 | 300 | 1430 | 350 | 480 |

| Puma | PES | 12 X 3MIPzB195 | 24 | 195 | 800 | 177 | 525 |

| Puma | PET | 2 x 6 x 3MIPzB195 | 24 | 195 | 428 | 175 | 520 |

| Puma | PET | 2 x 6 x 4MIPzB160 | 24 | 160 | 332 | 260 | 370 |

| Puma | 2 x 6 x 6MIPzB240 | 24 | 240 | 490 | 450 | 420 | |

| Puma | 2 x 24 x 5MIPzB500 | 48 | 500 | 975 | 405 | 755 | |

| Swaraj | FB Forklift | 24 x 10MIPzB650 | 48 | 650 | 1000 | 825 | 580 |

| Voltas | 1.5 Ton | 18 x 10MIPzB650 | 36 | 650 | 990 | 641 | 533 |

| Voltas | 2.0 Ton | 18 x 11MIPzB715 | 36 | 715 | 990 | 641 | 533 |

| Voltas | 2.0 Ton (Old) | 18 x 12MIPzB780 | 36 | 780 | 990 | 641 | 533 |

| Voltas | 2.5 Ton (Old) | 18 x 11MIPzB825 | 36 | 825 | 990 | 665 | 575 |

| Voltas | 2.5 Ton | 18 x 12MIPzB900 | 36 | 900 | 990 | 665 | 575 |

| Voltas | 2 Ton (New)/EVX15/EVX20/EVX25 | 24 x 8MIPzB520 | 48 | 520 | 902 | 718 | 518 |

| Voltas | 2.5 Ton (New)/EVX25/EVX30 | 24 x 8MIPzB600 | 48 | 600 | 902 | 718 | 625 |

| Voltas | BT Truck | 24 X 4MIPzS620 | 48 | 620 | 1208 | 579 | 905 |

| Voltas | 3 Ton/EVX 30 | 24 x 12MIPzB900 | 48 | 900 | 990 | 865 | 600 |

| Voltas | 5.0 Ton | 36 x 12MIPzB900 | 72 | 900 | 1285 | 1000 | 600 |

Please click to view certificate

- Microtex Limitless traction batteries are supplied suitably packed for distant transport within India or for exports on pallets in sea worthy packing

- Lead plated electrolytic grade flexible copper inter-cell bolt-on cables or welded connectors of rated capacity

- Terminal take off cables of suitable length to connect to forklift

- Internationally used standard Anderson plugs of rated capacity

- safety goggles, gloves, utility funnel, brass wire brush, sulfation protection – petroleum jelly sachet

- Instruction & maintenance manual

- Charging manual & user record book

- Peace of mind with our dedicated all India service support

- In India – one tree sapling to promote a green environment

Often taken for granted until things go wrong, batteries require some small maintenance and care. Traction Flooded Batteries are made up of several 2V lead-acid cells, which need an equalizing charge every month to prevent imbalance and capacity loss and to bring up all the cells up to the same voltage. Leave this to the battery experts at Microtex

We shall be happy to maintain your forklift batteries and help protect your investment. Call us now & inquire about our friendly service package for your traction batteries +91 9686 448899

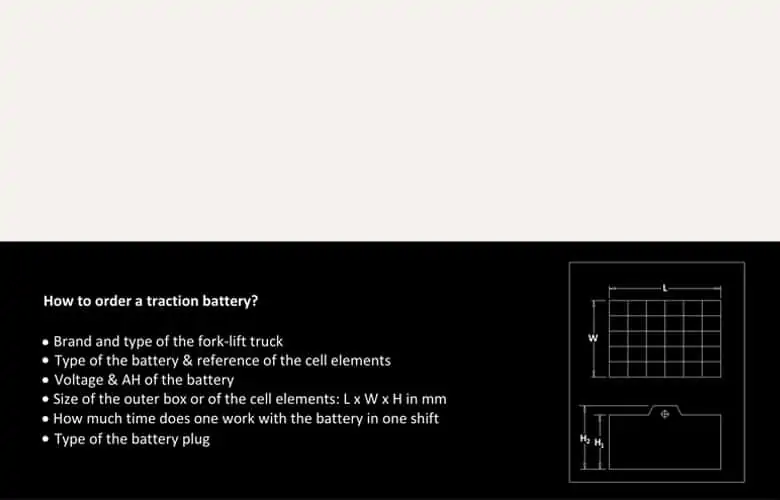

Please provide us with the following information to ensure that you receive the right product for years of great performance:

- What is the required total battery voltage & Ah

- Is the nameplate of the existing battery available? if yes please send us a photo

Please click the link below to view:

Industry-leading European Battery Experts work with us

The best experts from the European battery, industry assist in the design of Microtex Forklift battery & Processes to European Standards – Making our electric forklift batteries globally accepted!

Microtex have been manufacturing & exporting forklift battery from 1977!

Microtex timeline

May, 1969

Established as mfrs of PVC Battery Separators & PT Bags

Mr A Govindan our Founder & first generation entrepreneur, establishes Microtex pioneering the manufacture of battery separators & Tubular Bags which were import substitutes at the time. He obtained a patent for the Pluri Tubular Bags in 1975

Feb, 1977

Started exporting Traction Batteries to USSR

Not many companies in the world have the rich experience of manufacturing & exporting traction batteries from 1977. Microtex have supplied over 4500 traction batteries a year during the period

March, 1985

Approved for supply of 2V batteries for Telecom

Started supplies of 2V flooded LMLA batteries to the state owned P&T

April, 1994

Approved for supply to Indian Railways

Batteries for rolling stock applications & stationary batteries for signaling applications.

July, 2003

launched INtelliBATT 12v TT inverter batteries

Highly successful Microtex 12V flooded batteries for the huge inverter battery markets

Feb, 2005

Started manufacture of VRLA Battery & TSEC approved

Microtex establishes manufacture of VRLA batteries for various applications. Obtained TSEC approvals for VRLA batteries from 2V 200Ah to 2V 5000Ah in a very short time. Supplies to BSNL, Idea, Airtel, Indus Towers, Huawei, Bharti infratel, Viom, etc

Apr, 2006

Dr Rusch, leading battery scientist joins Microtex

Dr Wieland Rusch, battery expert from Germany & inventor of copper stretch metal submarine batteries, joins Microtex to upgrade & bring to world class designs for the complete range of batteries including traction battery & developed the complete range of OPzS & OPzV Gel battery. Microtex was the first company to launch Gel batteries in India.

Apr, 2008

Started production of OPzS & OPzV battery

Microtex started supplies of 2V OPzS Batteries to Nuclear facilities in India & exported Gel batteries for various applications including telecom, solar energy storage

Mar, 2011

Dr McDonagh joins Microtex as CTO

Dr Michael McDonagh with his rich manufacturing experience in various leading battery companies, established strong process controls in Microtex

2021

Fast forward to today

Microtex is legendary for its high quality batteries & reputed in the battery industry for its good & ethical business practices. Microtex manufacturing plant is environment friendly, involves employees & ensures their welfare is first. Microtex is probably one of the few companies worldwide to manufacture in house, the entire battery from the lead alloys, battery containers, the grid castings, plate manufacture, assembly & testing of batteries to world class standards.

Why choose a Microtex Forklift battery?

Technical information & unique characteristics

- Special powder coated steel trays to 150 microns will not chip or corrode in use

- Unique coating inside the tray to eliminate shorts & ground voltage in case of accidental over filling during topping up.

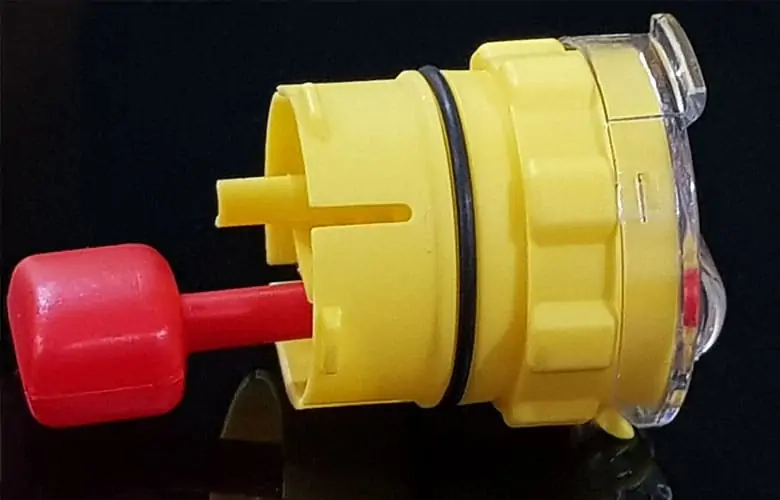

- Unique Japanese design vent plug with visual float level indicator for easy checking of acid level without opening each plug

- Designer lead alloys with low antimony, tin, selenium, arsenic for positive electrodes & special additives for negative electrodes to prevent failure due to corrosion

- Lower antimony ensures lesser water topping up requirements. With a Microtex Limitless battery it feels like a water less battery

- Accurately balanced active materials ensure overcharge tolerance giving you long life & trouble free performance

- Cured & formation processed plates - ensures high-quality

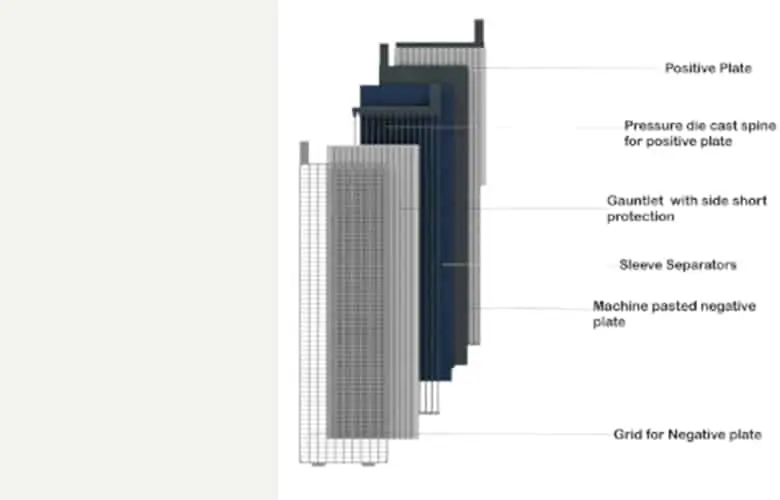

- Superior Woven Tubular Gauntlets (not NONWovens) for tubular electrodes. Woven tubular gauntlets will not rupture in service and active material will not leak causing internal shorts & failure

- High-quality flexible copper intercell connectors for bolt-on cells or hardened lead connector for welded cells with accurate current rating design

Robust construction

- Thicker spine grids & busbar ensure better compaction of lead, can withstand corrosion & provides longer life

- Incredible 150 Bar pressure die casted spine grids for positive tubular electrodes (densely compacted under such high pressures prevent early corrosion failures)

- Poly Propylene copolymer (PPCP) container specially designed for a hermetically strong bonded heat sealing of container to lid

- Special plastic coated, corrosion resistant bolts - with port, to take easy voltage measurements

- Plastic shrouds on connectors ensure no accidental shorts

- Factory Charged Batteries – No fuss no mess. Use straight away, saves time

- Microtex invests years of in-house experience. Our world-renowned battery scientists and experts continuously test and improves our products. Because of this, you’ll receive a more efficient battery than you are likely to buy elsewhere

You get -

- The complete international range available from 40Ah to 1400Ah in BS & DIN designs

- Traction battery are available in bolt-on design or welded design

- High capacity tubular battery with deep discharge characteristics recovers from deep cycles quickly

- Trouble-free performance

- Delivers the rated capacity

- We ensure our forklift battery price is among the most competitive in the industry

with more benefits for you

- Long service life - Best return on investment costs

- Low water consumption – less frequent maintenance – very low maintenance costs

- Excellent Reserve Capacity- Designed to sustain PSoC up to six months

- Higher charge efficiency = ampere-hour efficiency of over 90%

- Deep-discharge capabilities with higher charge efficiency = ampere hour efficiency of over 90%

- All India service network

Here is the perfect solution if you want

trouble-free forklift battery performance

How long do forklift batteries last?

Experience shows that 90% of batteries last only 3 to 4 years.

Don’t let that happen! Choose long-lasting deep-cycle batteries from Microtex. Dependable lead acid battery capacity so you can get the complete performance of over 5 years. Your return on investment in Microtex Limitless traction batteries ensures the long term cost is way lower.

What is the cost of forklift battery?

Special designer lead alloys, with super additives, tin, low-antimony, arsenic, ensuring a really long life for your Microtex Limitless™ Forklift battery. In addition, we add nucleating agents like selenium, sulfur & copper to ensure the lead electrodes do not corrode for a long time, ensuring a very long life. The addition of nucleating agents gives the grids a fine-grained structure with good corrosion resistance as otherwise, the coarse dendritic structure will be prone to hot cracking and porosity.

Most warehousing operations will use lead-acid batteries and lithium-ion batteries as their primary battery types to power their forklifts.

The electrical energy cost for charging one forklift at a rate of 4 cents per kWh is $490, which translates to $4896 for all ten forklifts.

How Long Do Forklift Batteries Last? Forklift batteries don’t last forever; a standard lead-acid forklift battery can produce approximately 1,500 charging cycles for a single-shift operation (if the battery is properly maintained).

The standard cell arrangement for 12 volt forklift batteries (6 cells) is a single row of 6 cells; for 24 volts (12 cells), it is either two rows of 6 cell each or three rows of 4 cells each; and for 32 volts (16 cells), there are three rows each.

Forklift batteries manufacturer in India for Forklifts & Stackers! Call Microtex for your urgent forklift battery requirements and get an immediate response!

Microtex Limitless Forklift Battery

Microtex Limitless Traction batteries

True deep cycle performance with woven guantlets

Specially double coated - eliminates ground voltage

German designs - Indian Engineering

Traction battery for forklifts, stackers, pallet jacks, forklift boom & platform trucks. Microtex forklift battery for material handling equipment industry.

Send us an inquiry, now.

Our happy customers

All logos belong to the respective companies & Microtex is not associated with the brands

Microtex Reputation. Highly demanding customer base

- OEM suppliers to forklift manufacturers

- leading manufacturing industries

- Indian Railways

- Oil companies

- Nuclear Power Corporation of India

- Exported globally

Get a quote, Now!

Established in 1969

Exporting Batteries to 43 countries since 1977!

Battery manufacturing plant in India

What Microtex customers experience

Related Batteries

- Semi Traction Batteries

- Golf Cart Batteries

- EV Batteries

- Semi Traction Batteries

- Mining Locomotive Batteries

Send us an inquiry, now.

Related Battery Blog Articles

Battery Mistakes All Forklift Owners Need To Avoid!

Do not mix new cells into old batteries

Forklift Battery recondition: often reconditioning an old battery can become quite a costly affair if you keep replacing dead cells one by one; even the new cell will drain out rapidly as the old cells tend to draw more out of the new one.

Forklift replacement batteries: It is best to have an expert from the company visit you to have a thorough inspection of the forklift trucks battery after a complete charge, compare the cell voltage, specific gravity

Avoid any sort of additives or desulfation methods

How to recondition forklift batteries? Batteries are electro-chemical devices. All chemicals have a half-life period beyond which regeneration with chemical additives or desulfators for batteries have little effect if any temporary.

The normal mode of failure of traction batteries is usually due to grid corrosion if the lead alloys are not designed properly. Desulfators cannot repair corroded grids.